GEI-68720

SERVICING AND ADJUSTMENTS

CONTACT CLEANING

In cleaning fine silver contacts a flexible burnishing tool should be used.

This consists of a flexible strip of metal with an etched, roughened surface,

resembling, in effect, a superfine file.

The polishing action is so delicate than

no scratches are left, yet corroded material will be removed rapidly and thoroughly.

Fine silver contacts should not be cleaned with knives, files, or abrasive

paper or cloth.

The burnishing tool described is included in the standard XRTllA relay tool kit

obtainable from the factory.

CONTACT ADJUSTMENT

The contacts should not require readjustment since they are self-aligning.

Any contact circuit can be changed (except as noted in the

CHARACTERISTIC

section) from circuit-opening to circuit-closing, or vice versa, by removing the

fixed contact, turning it over and returning it to its place.

If for any reason it becomes necessary to readjust the contacts, for instance

if a contact is changed from circuit-opening to circuit-closing, the following

checks and adjustments should be made;

1.

Make sure that all contact and coil studs are tight.

2.

Make sure that the armature is free of binding when operated by hand.

The

braided 11pigtail11 lead on all contacts must be adjusted to exert minimum force

on the contacts.

3

Make mechanical contact adjustments as follows:

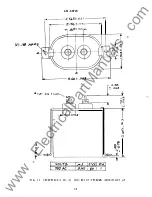

3.1. Normally-Open Contacts, Wipe and Gap

(Normally-open contacts must be adjusted

before normally-closed contacts.)

a.

The moving contact arms must be adjusted so that the normally-open

contacts make approximately simultaneously (�.008) when the relay is

operated by hand.

All normally-open contacts must have a wipe of 3/64 to

3/32 inches.

The contact gap must be approximately 7/32 inch.

This can

be adjusted as follows:

i)

Insert a 0.058 gage between the armature and pole face and close the

armature.

ii) Bend the left-hand moving contact to just light the continuity lamp.

iii) Remove the 0.058 gage and bend the remaining moving contacts so that

all moving contacts make at approximately the same time.

8

www

. ElectricalPartManuals

. com