03

04

3 Product Introduction

3.1 Intended Usage

The GEP series which is a Three or Six MPPT, three phase transformer-less grid-connected

inverter which is a crucial unit between the PV string and the utility grid in the PV power system.

Inverter is dedicated to converting directing current generated by the PV module into alternating

current, and feeding it into the utility grid, this conforms to parameters of the local utility grid. The

intended usage of inverter is illustrated in the below figure.

kW.H

A

B

C

D

GEP series

GEP12-L-10,GEP15-L-10,GEP20-L-10,GEP25-10,GEP30-10,GEP36-10,GEP29.9-10,GEP30-L-1

0,GEP35-L-10,GEP50-10,GEP60-10 support four different types(TN-S,TN-C,TN-C-S, TT) of grid.

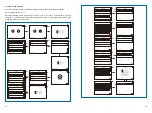

please refer to the below figure.

The reason why the inverter can't be connected to the PV module is that the positive or

negative terminal should be grounded, except when a transformer has been used between

the inverter and grid.

Item

A

B

C

D

Description

PV string

Inverter

Meter device

Utility grid

Note

Monocrystalline silicon, polycrystalline silicon and others.

GEP Series

Meter cupboard with distributed generation system

TN-S, TN-C, TN-C-S, TT, IT

(different Model types with different types of utility grid as below)

TN-S

TN-C

TN-C-S

TT

L1

L2

L3

N

PE

PE

Transformer

Inverter

Transformer

L1

L2

L3

PEN

PE

Inverter

L1

L2

L3

N

PE

Transformer

PE

Inverter

L1

L2

L3

N

Transformer

PE

Inverter

2 Safety Measures & Warning

This manual contains important instructions for GEP series inverter that shall be followed during

installation of the inverter.

The GEP series for Three or Six MPPT, Three-Phase solar inverter without transformer, which

consists of GEP12-L-10, GEP15-L-10, GEP20-L-10, GEP25-10, GEP30-10, GEP36-10,

GEP29.9-10, GEP30-L-10,GEP35-L-10,GEP50-10 and GEP60-10 model type.

GEP Series have been designed and tested strictly according to the international safety regula-

tion. As electrical and electronic equipment, safety instructions related to them must be complied

with during installation, commissioning, operation. Incorrect or improper work may result in

damage to:

1. The life and well-being of the operator or a third party.

2. The inverter and other properties that belong to the operator or a third party. Therefore the

following safety instructions must be read and always kept in mind prior to any work. All detailed

work-related safety warnings and notes will be specified at the critical points in corresponding

chapter.

All installation and electrical work must only be performed by qualified personnel. They have:

•Been trained specially.

• Already completely read through and understood the manual and related documents.

• Be familiar with safety requirements for electrical systems.

The inverter must be installed and maintained by professionals in compliance with local electrical

standards regulations and the requirements of local power authorities or companies.

• Improper handling of this device will pose a risk of injury.

• Always follow the instructions contained in the manual when moving or positioning the inverter.

• The weight of the equipment can cause injuries, serious wounds or bruise if improperly handled.

• Please install it in a place beyond children's reach.

• Prior to installing and maintaining the inverter, it is crucial to make certain that the inverter in not

electrically connected.

• Before maintaining the inverter, disconnect the connection between the AC grid and the inverter

first, and then disconnect the connection between the DC input and the inverter, you should wait

at least 5mins after these disconnection in case of electric shock.

• All cables must be firmly attached, undamaged, properly insulated, and adequately dimen-

sioned.

• The temperature of some parts of the inverter may exceed 60

℃

during operation. To avoid

being burnt, do not touch the inverter during operation. Let it cool before touching it.

• Without permission, opening the front cover of the inverter is not allowed. Users should not

touch/replace any components of the inverter except the DC/AC connectors. Manufacturer will not

bear any consequences caused by unauthorized actions which will lead to potential injury to

people and damage to inverters.

• Static electricity may damage electronic components. Appropriate method must be adopted to

prevent such damage to the inverter; otherwise the inverter may be damaged and the warranty

will be annulled.

• Ensure that the output voltage of the proposed PV array is lower than the maximum rated input

voltage of the inverter; otherwise the inverter may be damaged and the warranty will be annulled.

• If the equipment is used in a manner not specified by the manufacturer, the protection provided

by the equipment may be impaired.

• When exposed to sunlight, the PV array will generate very high voltage which can cause

electrical shock hazard. Please strictly follow the instruction we provided.

• PV modules should have an IEC61730 class A rating.

• Prohibit inserting or pulling the AC or DC terminals when the inverter is operational. Or the

inverter will be destroyed.

Only DC connectors provided by Manufacturer are permitted for use, otherwise the inverter may

be damaged and the warranty will be annulled.

• The inverter can exclude the possibility of DC residual currents to 6mA in the system,Where an

external RCD is required in addition to the built-in RCMU, type A RCD must be used to avoid

tripping.

• The default photovoltaic module is not grounded.

• It is recommended to add a fuse when there is more than two PV string inputs into one MPPT.

The IP65 premise is that the machine is completely sealed. Please install it within one day after

unpacking, otherwise please block the unconnected port and do not open it to ensure that the

machine is not exposed to water and dust.

Summary of Contents for GEP

Page 24: ......