Installation Instructions

EXHAUSTING THE DRYER

- Fire Hazard

WARNING

This dryer MUST be vented to the outdoors.

Use only 4” rigid metal ducting for the home

exhaust vent.

Use only 4” rigid metal or UL-LISTED transition duct

to connect the dryer to the home exhaust duct.

DO NOT

use a plastic vent.

DO NOT

exhaust into a chimney, kitchen exhaust,

gas vent, wall, ceiling, attic, crawl space, or

concealed space of a building.

DO NOT

install a screen in or over the exhaust duct.

DO NOT

use duct longer than specified in the

exhaust length table.

Failure to follow these instructions can result in

death or fire.

8

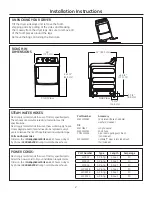

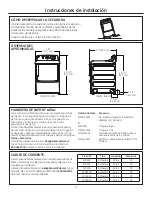

TOOLS AND MATERIALS YOU WILL

NEED TO INSTALL EXHAUST DUCT

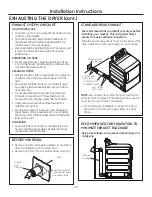

CONNECTING THE DRYER TO HOUSE

VENT

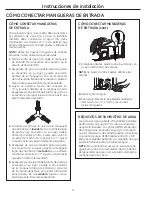

RIGID METAL TRANSITION DUCT

•

For best drying performance, a rigid metal transition

duct is recommended.

•

Rigid metal transition ducts reduce the risk of crushing

and kinking.

UL-LISTED FLEXIBLE METAL CLOTHES DRYER

TRANSITION DUCT

•

If rigid metal cannot be used, then UL-LISTED flexible

metal clothes dryer transition duct (GE parts –

PM08X10085, WX08X10085 or WX08X10077) can be

used.

•

Never install transition duct in walls, ceilings, floors or

other enclosed spaces.

•

Total length of transition duct should not exceed

8’ (2.4 m).

•

For many applications, installing elbows at both

the dryer and the wall is highly recommended (see

illustrations at right). Elbows allow the dryer to sit

close to the wall without kinking and/or crushing the

transition duct, maximizing drying performance.

•

Avoid resting the duct on sharp objects.

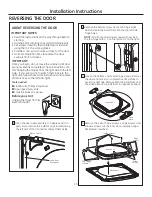

UL-LISTED FLEXIBLE METAL (FOIL-TYPE) TRANSITION

DUCT

•

In special installations, it may be necessary to connect

the dryer to the home exhaust vent using flexible metal

(foil-type) transition duct. UL–LISTED universal flexible

dryer transition duct (GE parts – PM8X73 or WX8X73)

may be used ONLY in installations where rigid metal or

flexible metal transition ducting cannot be used AND

where a 4” diameter can be maintained throughout

the entire length of the transition duct.

•

In Canada and the United States, only transition ducts

that comply with “

UL 2158A STANDARD FOR CLOTHES

DRYER TRANSITION DUCT

” shall be used.

•

Avoid resting the duct on sharp objects.

•

For best drying performance:

1. Slide one end of the duct over the clothes dryer

outlet pipe.

2. Secure the duct with a clamp.

3. With the dryer in its permanent position, extend

the duct to its full length. Allow 2” of duct to

overlap the exhaust pipe. Cut off and remove

excess duct. Keep the duct as straight as

possible for maximum airflow.

4. Secure the duct to the exhaust pipe with the

other clamp.

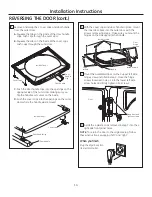

PARTS AVAILABLE FROM LOCAL

SERVICE ORGANIZATIONS

• Rigid Metal Duct Components

WX8X63

4 x 1 Duct

WX8X64

4 x 2 Duct

WX8X51

4 Elbow

WX8X59

4 Aluminum Hood

• Flexible Metal Duct Components

WX8X58

4 Clamps (2)

WX8X59

4 Aluminum Hood

WX08X10077

6 UL-Listed, Flexible Metal (Semi-Rigid)

Duct, 2 Clamps, 2 Close Elbows

WE1M454

Cover rear exhaust opening

Phillips-head

screwdriver

Duct tape or

duct clamp

Rigid or UL-listed

flexible metal 4”

(10.2 cm) duct

Drill with 1/8” drill bit

(for bottom venting)

Hacksaw

Vent hood