Summary of Contents for ApexPro T14

Page 9: ...2001989 351A ApexPro vii ...

Page 10: ...viii ApexPro 2001989 351A ...

Page 11: ...2001989 351A ApexPro 1 1 1 Introduction ...

Page 20: ...1 10 ApexPro 2001989 351A Introduction ...

Page 21: ...2001989 351A ApexPro 2 1 2 Equipment Overview ...

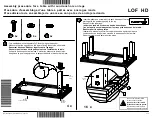

Page 41: ...2001989 351A ApexPro 3 1 3 Installation and configuration ...

Page 62: ...3 22 ApexPro 2001989 351A Installation and configuration ...

Page 63: ...2001989 351A ApexPro 4 1 4 Maintenance ...

Page 84: ...4 22 ApexPro 2001989 351A Maintenance ...

Page 85: ...2001989 351A ApexPro 5 1 5 Troubleshooting ...

Page 109: ...2001989 351A ApexPro 6 1 6 Replaceable parts ...

Page 138: ...6 30 ApexPro 2001989 351A Replaceable parts Quad receiver module ...

Page 139: ...2001989 351A ApexPro 7 1 7 Checkout ...

Page 163: ...2001989 351A ApexPro A 1 A Technical specifications ...

Page 179: ...2001989 351A ApexPro B 1 B Electromagnetic compatibility ...

Page 190: ...B 12 ApexPro 2001989 351A Electromagnetic compatibility ...

Page 191: ...2001989 351A ApexPro 1 1 ...