13

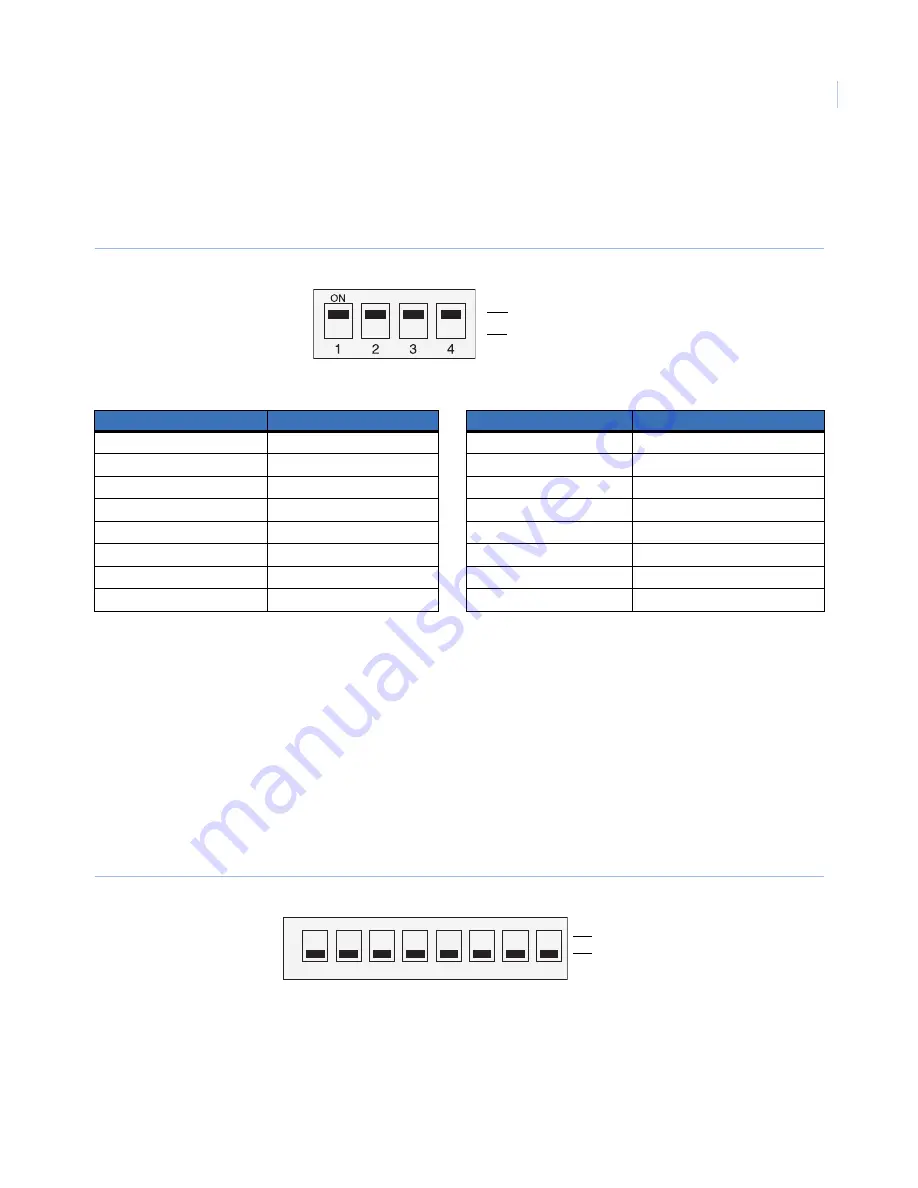

3. The SW101 DIP switch on the bottom of the camera (

Figure 15

) sets the protocol. Use

Table 4

to find

the correct sequence of 1s (on) and 0s (off) for the protocol that you want to use.

Note:

SW101 is located on the opposite side of the board from the 8-bit camera ID DIP switch.

Figure 15. SW101

4. Power up the camera to load the changes.

Camera ID setting

The camera’s ID is set to “1” as default. If you use two or more cameras simultaneously, change the ID of the

cameras.

To set the camera ID, do the following:

1. Locate the 8-bit camera ID DIP switch block on the bottom of the camera.

2. Using

Figure 16

and

Table 5

, determine how to set the DIP switches for the desired camera ID.

3. Place the switches that correspond to those values in the on position.

Figure 16. Camera ID DIP switch

Table 4.

SW101 protocol settings

Switch position

Protocol

Switch position

Protocol

1, 1, 1, 1

Digiplex 422 (default)

1, 1, 1, 0

Reserved 7

1, 0, 1, 1

ASCII

0, 1, 1, 0

Reserved 8

0, 1, 1, 1

IMPAC RS-485

1, 0, 1, 0

Reserved 9

0, 0, 1, 1

Pelco-D

0, 0, 1, 0

Reserved 10

1, 1, 0, 1

Pelco-P

1, 1, 0, 0

Reserved 11

0, 1, 0, 1

Reserved 4

0, 1, 0, 0

Reserved 12

1, 0, 0, 1

Reserved 5

1, 0, 0, 0

Reserved 13

0, 0, 0, 1

Reserved 6

0, 0, 0, 0

Reserved 14

On (1)

Off (0)

On (1)

Off (0)

Equivalent value 1 2 4 8 16 32 64 128

ON

1

2

3

4

5

6

7

8

Summary of Contents for PTZ

Page 1: ...g GE Security 1063759A GE 16X PTZ Installation Manual...

Page 4: ...GE 16X PTZ Camera Installation Manual iv...

Page 22: ...GE 16X PTZ Camera Installation Manual 18 Figure 22 Safety cable to camera...

Page 23: ...19 6 Connect the cable to the terminal on the camera body Figure 23 Figure 23 Cable connection...

Page 37: ...33 6 Connect the cable to the terminal on the camera body Figure 23 Figure 40 Cable connection...