12/72

EN

8.4. PRODUCT LIFE TIME

8.4.1. PRODUCT LIFE TIME AND WASTE MANAGEMENT

Maximum life time of the product is 10 years.

At the end of the product’s life time, the product must be withdrawn from service.

The owner shall put in place a relevant procedure to ensure the product cannot be used again.

The owner of the device shall prevent the reuse of the product and handle the product in

compliance with “Directive of European Parliament and Council 2006/12/ES of 5th April 2006

on waste“.

In accordance to Article 33 of REACH GCE, s.r.o. as responsible manufacturer shall inform all

customers if materials containing 0.1% or more of substances included in the list of Substance

of Very High Concern (SVHC).

The most commonly used brass alloys used for bodies and other brass components contain

2-3% of lead (Pb), EC no. 231-468-6, CAS no. 7439-92-1. The lead will not be released to the gas

or surrounding environment during normal use. After end of life the product shall be scrapped

by an authorized metal recycler to ensure efficient material handling with minimal impact to

environment and health.

To date we have no information that indicates that other materials containing SVHC of

concentrations exceeding 0.1% are included in any GCE product.

8.4.2. SERIAL NUMBER AND DATE OF PRODUCTION

Form of nine digit serial number stamped on the product is following:

YY MM XXXXX

YY: year of production

MM: month of production

XXXXX: sequence number

Example: serial number 090300521 shows the product produced in March 2009, with sequence

number 521.

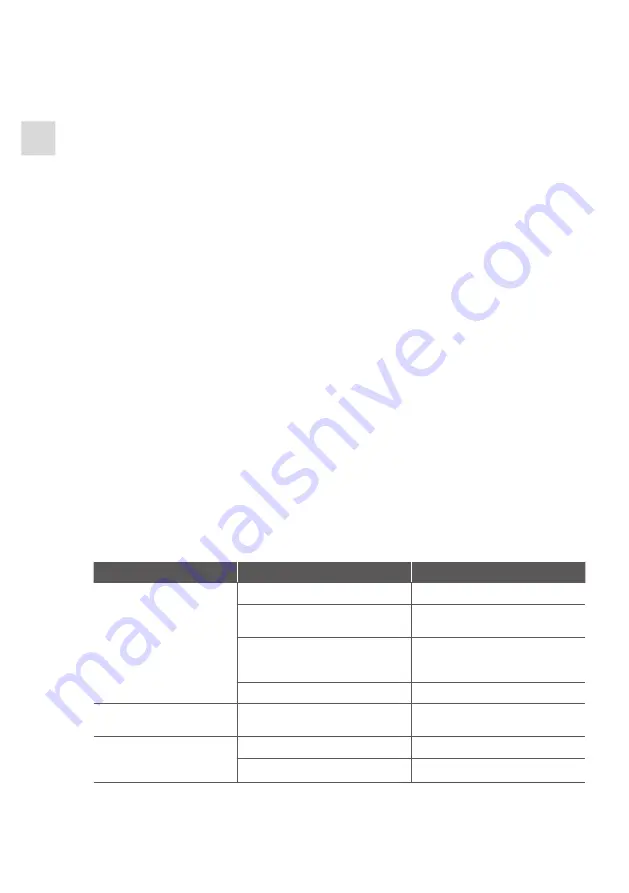

9. TROUBLESHOOTING

The table below is provided as a means of correcting simple faults with the equipment. If the

suggested remedies do not rectify the fault, the equipment must be returned for inspection

and rectification by trained personnel who have completed the relevant training course (see

Section 8.2).

Symptoms

Possible Cause

Corrective Action

Equipment does not

deliver gas.

Cylinder valve not turned on.

Check and turn on cylinder.

Cylinder empty.

Check contents gauge. Fit a new

cylinder if necessary.

Quick coupling is not fully

connected.

Remove probe and re-fit to

adaptor, ensuring that it is fully

engaged.

Exhalation valve flap missing.

Fit a new exhalation valve flap.

Demand valve leaks or

does not shut cleanly.

Adjustment incorrect.

Refer to Service Manual

Demand valve does not

stop giving flow after test

button is released.

Inhalation disc warped / damaged.

Fit a replacement inhalation disc

Incorrect adjustment.

Refer to Service Manual

Summary of Contents for EASE II

Page 2: ......