19/24

EN

Line pressure regulators are used to reduce a higher tube pressure to a certain low supply pressure level.

They remain constantly installed inside the tube system. Pressure regulators LMD 500:

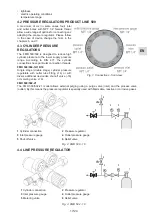

Fig. 4: Flow scheme FMD 500 - 21

1

Cylinder connection

2

Pressure regulator

3

Inlet pressure gauge

4

Outlet pressure gauge

5

Process gas valve

6

Relief valve

7

Purge gas valve

8

Non-return valve

5

4

8

1

6

2

3

7

Single stage line pressure regulator in different design with six (LMD 500-03) or only four (LMD 500-01)

in- and outlet connections. Pressure regulators LMD 502: Double stage line pressure regulator supplying

constant level outlet pressure (virtually independent of the inlet pressure) with six (LMD 502-03) in- and

outlet connections.

Fig. 5: Single stage LMD 500 - 03 and double stage LMD 502 - 03

with inlet and outlet pressure valve

4.5 POINT OF USE PRESSURE REGULATOR

Point of use pressure regulators are installed at the end of central gas supply systems. The are designed

to reduce the line pressure to the desired low pressure level of gas consuming device. EMD 500: Standard

design (EMD 500-06) with inlet shut-off valve, pressure regulator, pressure gauge and fixing panel.

4.6 DIAPHRAGM VALVES

Fig. 6: EMD 500-06

1

Eingangsabsperrventil

2

Druckminderer

3

Hinderdruckmanometer

3

1

This product line is distinguished by a great reliability, low leakage and longlife endurance. Shut-off valves

and metering valves are as well deliverable in straight (G) or angel version (W).

MVA 500 G/W SHUT-OFF VALVE

The shut-off valve is simple to operate, with 90° turn and click effect. The open/shut position is clearly

recognizable: handwheel parallel to gas line – valve open. Handwheel at right angles to gas line – valve

closed.

MVR 500 G/W METERING VALVE

Fine dosing metering valve with good control characteristics at high and low flow levels. (at maximum 10

knob turns open to closed). Please keep attention: only shut-off valves guarantee the secure interruption

of gas flow.

4.7 ACCESSORIES

An extensive range of accessories is available for the 500 series. This includes screwed fittings, hose

nozzles, contact pressure gauges and flashback arresters. For further information please contact the

manufacturer. The assembly and installation instructions for these components must be observed.

IDENTIFICATION

5.

Fig. 7: Cylinder pressure regulator to connect to

gas cylinder to connect to gas cylinder

Seal

The rating plates provide the following information:

Manufacturer, date of manufacture, type designation,

permissible inlet pressure (pein), device-specific outlet

pressure range (paus), materials of regulator body and

seal gasket, safety information, and gas type symbol.

The serial number is provided as a device-specific

identification on a separate plate in bar code 128 and

in type.

Please use only pressure device suitable to gas

type and pressure predescriped on the rating plate

and labelling. Thread of danger to life and health of

persons and/or damage of pressure device.

Manufacturer

Attention!

Pressure device.

Service only by

autorised persons

He

Typ: EMD 400-01

Mat: Ms / Ni / PVDF

Pin: 40 bar

Pout: 0,5 - 10 bar

95.10.

INSTALLATION

6.1 CYLINDER PRESSURE REGULATORS

The threads of the cylinder valve and the union nut

must be in impeccable condition.

Always use new gaskets. Gaskets must not be

deformed and must show no traces of dirt or metal

turnings.

Attention: Do not use spanner extensions because

they may destroy the thread and the gasket. This can

lead to leaks or to complete and uncontrolled loss of

the gas supply.

6.

Fig. 8: Assembly of pressure regulator

to the gas cylinder

When connecting or changing cylinders containing toxic or corrosive gases, appropriate personal

protection measures must be taken (respiratory protection, eye protection and protective clothing).

Observe the MAK values (maximum workplace concentration value; see Technical norms for

dangerous substances, TGRS 900) and have the correct respiratory protection filters at hand..

Before connection, check the rating plate to determine whether the equipment is suitable for the

intended use (type of gas, pressure, etc. see section 5).

Summary of Contents for druva LINE 200

Page 12: ......