21/24

EN

Before switching on the pressure device ensure that no-one can be put in a situation of danger by

starting up the pressure device.

Use only pressure device with external gas purging when working with toxic, corrosive or pyrophoric

gases.

PREPARATION

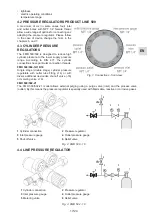

Take care that process and purge gas lines are connected gas tight to the appropriate in- and outlets. Turn

the handwheel of the regulator counter-clockwise, thereby closing the valve gate. Close all valves.

LEAKAGE TEST

Open the cylinder valve and close immediately. Spray leakage test spray over the cylinder connection. If

there results a formation of bubbles, tighten the cylinder connection until the formation of bubbles stops. If

seals have been changed, repeat the leakage test after 24 hours respective tighten the cylinder connection

again.

EXTRACTING PROCESS GAS

Slowly open the cylinder valve. Watch the inlet pressure gauge. Set the desired outlet pressure by turning

the regulator handwheel clockwise. Set the desired flow volume on the metering valve (if applicable).

CYLINDER CHANGE

When changing cylinders with toxic or corrosive gases the necessary personal safety measures

must be taken (respiratory protection, eye protection and protective clothing.) Observe the MAK

values (see Technical norms for dangerous substances, TGRS 900) and have the correct respiratory

protection filters at hand.

Did you use corrosive or toxic gases, you have to purge the pressure device with inert gas (see

chapter 6.2 ”External gas purging”). This will ensure that the remaining dangerous gas will be

purged completely.

PREPARATION

1.

Tightly close the shut-off valve on the gas cylinder. Close the inlet valve.

2.

Open the outlet pressure valve, if there is any. Empty the pressure regulator completely by turning the

handwheel clockwise. The indicators on the inlet and outlet pressure gauges must both be all the way

on „0“.

3.

Turn the handwheel of the regulator counter-clockwise as far as possible (valve gate closed).

4.

Close the process gas valve.

CYLINDER CHANGE

Using cylinder pressure regulator FMD 500/502-21, you have to purge at first. Loosen the union nut on the

gas cylinder using a spanner. Control the threats. Change the seal. Connect the new cylinder following the

steps above (see chapter 6.2). Make a leakage test (following the steps above).

TAKING OUT OF OPERATION

Release the pressure on pressure controller and lines by directing the gas to the consumer. The

indicators on the inlet and outlet pressure gauges must be all the way on „0“. With corrosive or

toxic gases, purge all components with inert gas. The necessary personal safety measures must be

taken (respiratory protection, eye protection and protective clothing.) Observe the MAK values (see

Technical norms for dangerous substances, TGRS 900) and have the correct respiratory protection

filters at hand.

9.1 CYLINDER PRESSURE REGULATORS

For a brief interruption of gas removal it is sufficient to close the shut-off valve on the regulator. For a longer

interruption the regulator must be released from pressure by turning the handwheel counter-clockwise.

Close the cylinder valve as a safety precaution.

9.2 SUPPLY PRESSURE REGULATORS

Close the preliminary shut-off valve.

9.3 LINE PRESSURE REGULATORS

Close the pressure regulator by turning counter-clockwise.

9.

8.

Summary of Contents for druva LINE 200

Page 12: ......