Jaguar V User Manua

l

Trouble Shooting 6-4

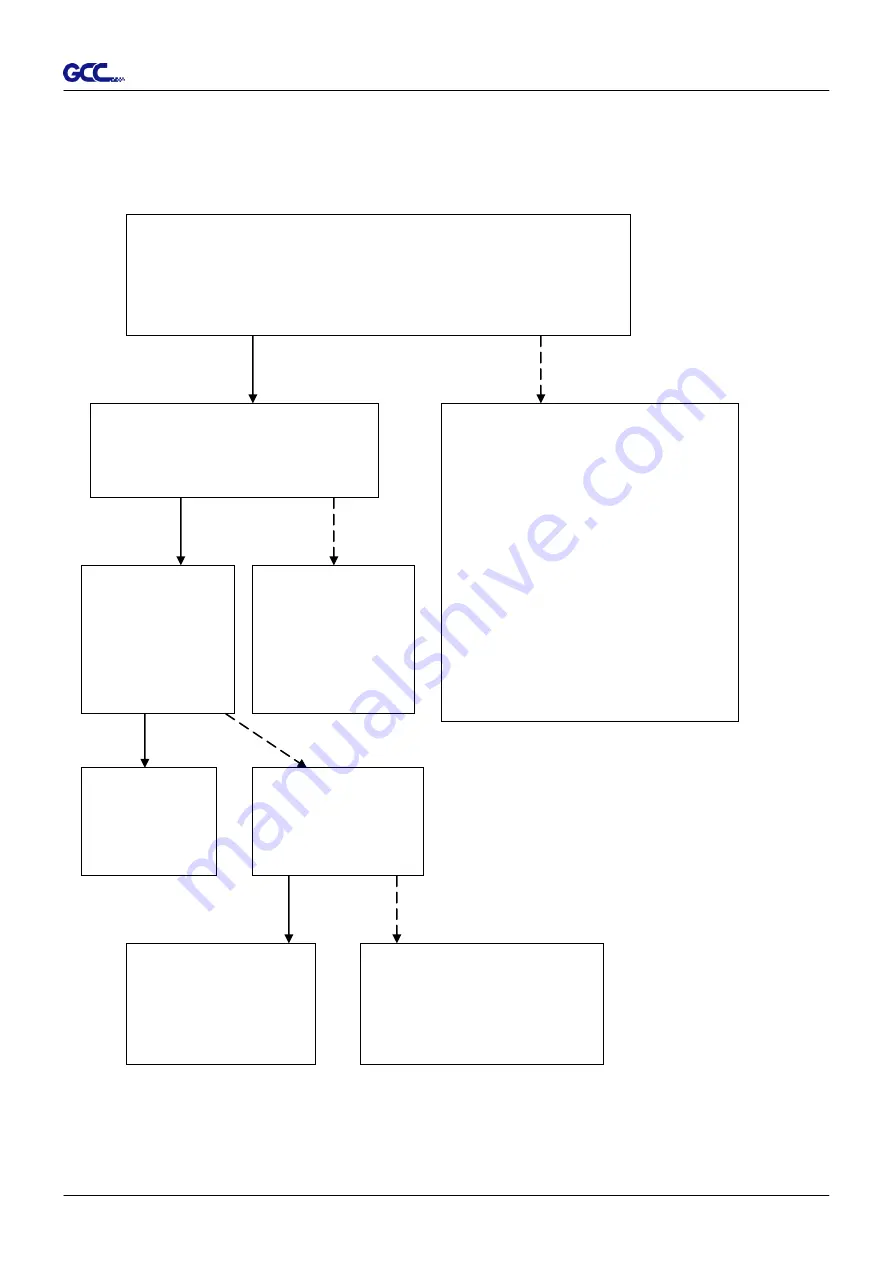

6.4 Software Problems

Check the following first:

Does your software package indicate that it will work with

your computer and cutting plotter?

Does your software support HP-GL and HP-GL/2 drivers?

(* check the configuration settings of your software.)

Yes

No

Does the cutting plotter interface

match the requirements of your

software?

Does your

software

recommend

using a different

cable?

Does the software

vendor provide a

sample file?

Most well known cutting softwares

in the world have drivers for our

cutting

plotters.

If

not,

use

software that has HP-GL and

HP-GL/2 emulation supports and

you can chose the following three

drivers:

A3 size: HP7475A

A1 size: HP7580A

A0 size: HP Draf Pro Exl or

HP Draf Master

Yes

No

Refer to Chapter

2 - Connecting

your cutting

plotter.

Yes

No

Try using the

recommende

d cable.

Yes

No

Re-power on the

cutting plotter and

try to send the file

again.

Do something about the

error message display on

LCM, or consult your

software vendor.