Expert 24 User Manual

Installation 2-8

CAUTION!

!!

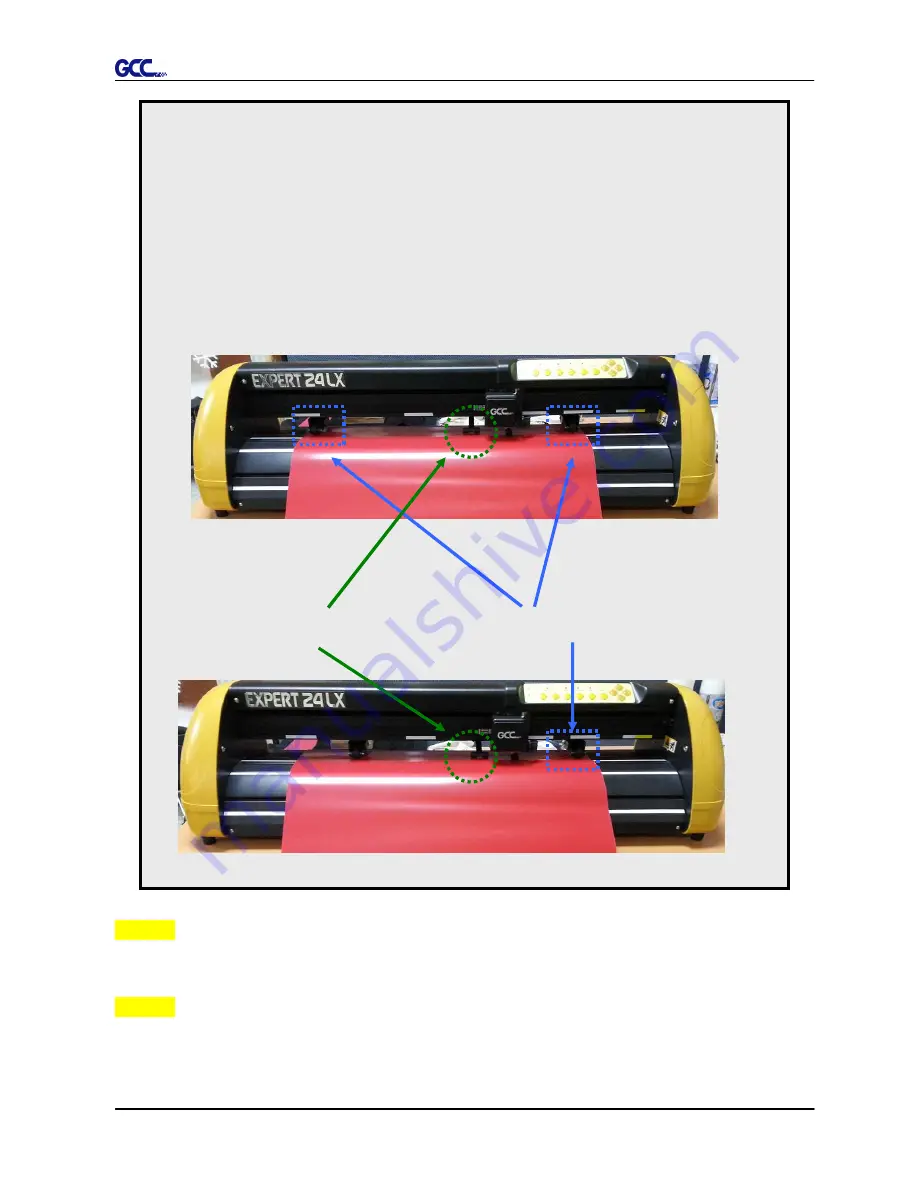

Make sure the Primary and secondary pinch rollers are set to right positions.

Position the Primary Pinch Rollers at the right and left sides of media.

Position the Secondary Pinch Roller at the center of media.

Figure 2-17

Primary Pinch Roller

Secondary Pinch Roller

(X)

Incorrect

(O)

Correct

Figure 2-18

Step 4

Push the lever backward to lower down the pinch rollers (Figure 2-15).

Step 5

After turn on the power, the tool carriage will measure the size of the media automatically. And

the plotting cutter begins to work.