GBC 5031TS

OPERATION MANUAL

© 2006 General Binding Corporation

11

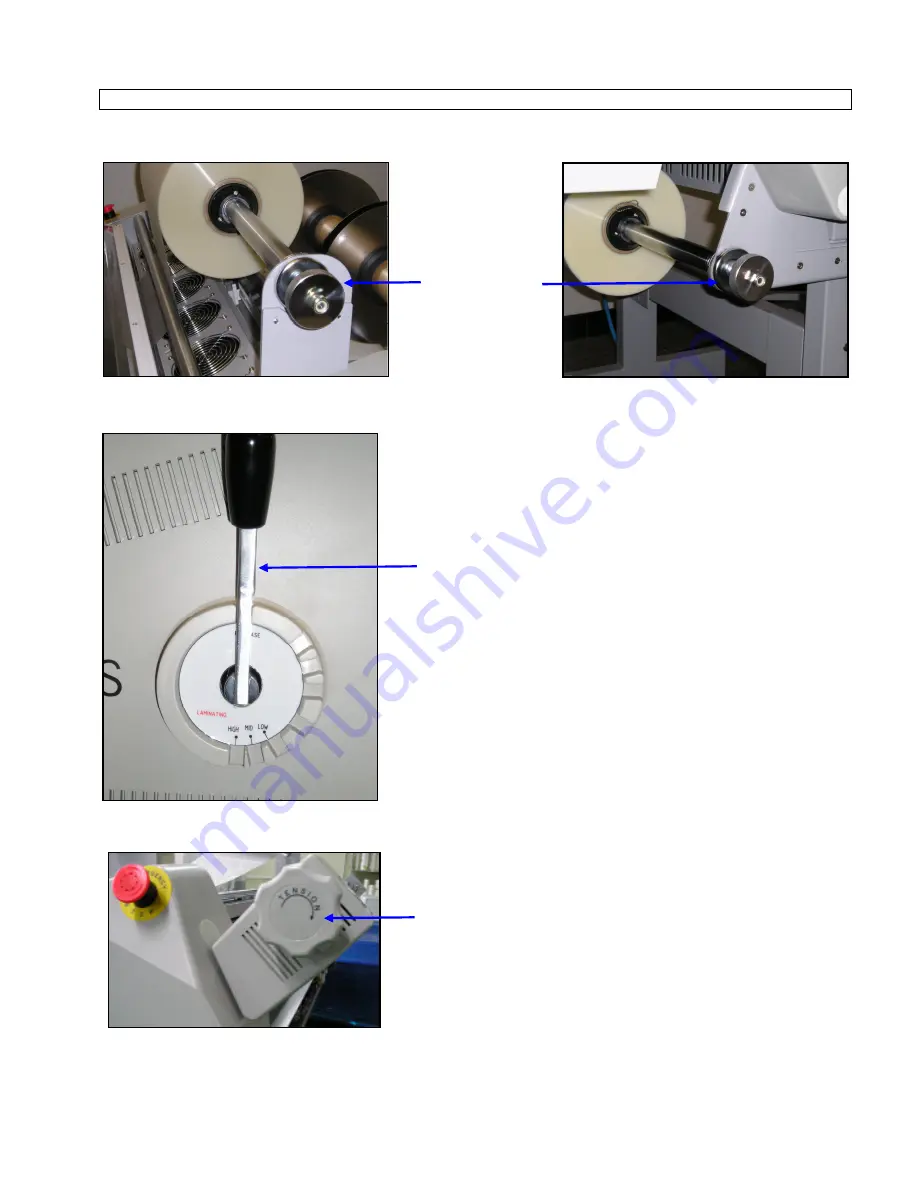

LAMINATOR CONTROLS

A. Top Brake

(Figure 15)

B. Bottom Brake

(Figure 16)

A. Roller Pressure Handle

(Figure 17)

Engages the nip and pull roller pressure

simultaneously.

Located on the right-hand side of the laminator.

Adjusts the amount of the roller pressure

needed for various laminating thicknesses.

There are three thickness settings:

a. Heavy material up to 1/6” (1mm),

including film.

b. 1.5 – 3.0 mil film (38 – 75 mic)

c. 5 mil film (125 mic)

d. 10 mil film (250 mic)

A. Scrap Rewind Clutch

(Figure 18)

Adjusts the tension on the Scrap rewind shaft.

Tighten only enough to make the shaft rotate.

Too tight a tension will make emptying difficult.

Note:

•

Clockwise rotation increases the break

tension

•

Counterclockwise rotation decreases the

brake tension

•

Always use the least amount of tension

possible to flatten out the film

•

Adjustments should be made at the selected

speed for the job

A

Figure 15

B

Figure 16

Figure 17

A

Figure 18

A