18

GAUI

TAI SHIH HOBBY CORPORATION

升級維修零件表

Upgrade & Replacement Parts

207152

H255 Landing Gear Skids combo pack(Black

anodized)

颶風 255 滑橇組合包(黑色)

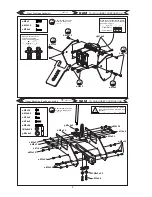

207430 Hurricane 255 Aluminum Frame posts

颶風255 碳纖側板鋁柱包

207500 H255 High Performance Stabilizer Blades

combo pack(40x21 mm)

颶風255高性能平衡片組合包(40x21 mm)

207501

H255 Ball links and Thread rods combo

pack(for Ball 3.5mm)

颶風255球頭扣及螺桿組合包(3.5mm球頭用)

207502

H255 Main Shafts Pack(3 x 89 mm)

颶風255 長主軸包(3 x 89 mm)

207505 H255 Balls & Extension for CNC Swashplate

combo pack

颶風255球頭及延伸桿組合包

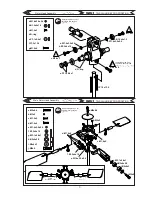

207506 H255 CNC Mixing Arms

颶風255 CNC 混控臂組

207507 H255 CNC Washout Base

颶風255 CNC 相位器(剪形臂座)

207508 H255 CNC Washout Base & Arms Assembly

颶風255 CNC 剪形臂及相位器組

207509 H255 CNC Swashplate Assembly

颶風255 CNC 十字盤組

207510 H255 CNC See-Saw Set

颶風255 CNC 平衡座組

207511 H255 CNC See-Saw Spindle

颶風255 CNC 平衡桿軸

207512 O Ring(Hardness 50) and Paper washer for

3mm Main Rotor Spindle

3mm 橫軸用O型環(硬度50)及紙墊片組

207513

Canopy Posts&H255 Damper Rubbers Pack(for

canopy)

颶風255艙罩支柱&橡膠減震包(座艙用)

207514 H255 Main Pulley Collars

(for High Performance Main Gear)

颶風255 主皮帶輪固定環(高性能主齒盤用)

207515 H255 Upper Mast Collar

颶風255 上主軸固定環

207516 One Way B. & Auto-rotation Main Gear Set

高性能同步自旋主齒盤附單向軸承組

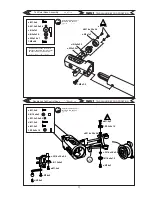

207517 H255 Swashplate Guide

颶風255十字盤滑軌

207518 H255 CNC Mast Mount

颶風255 CNC主軸座

207519 H255 CNC Motor Mount

颶風255 CNC馬達座

207520 H255 CNC Swashplate Guide

颶風255 CNC十字盤滑軌

207600 B.(1.4x4x1.35)x2pcs (for H255)

颶風255 軸承包(1.5x4x1.35)x2個

207601 B.(2x5x2.5)x3pcs (for H255)

颶風255 軸承包(2x5x2.5)x3個

207602 B.(3x6x2.5)x2pcs (for H255)

颶風255 軸承包(3x6x2.5)x2個

207603 B.(3x6x2)x2pcs (for H255)

颶風255 軸承包(3x6x2)x2個

207604 B. for H255 Main Gear

颶風 255主齒盤軸承包

207605

Countsunk Washer and Mechine Screw

set(M2x3.2)x10

沉頭墊片及機械牙螺絲組(M2x3.2)x10組

207606 Mechine Screws(M1.4x3)(M1.4x5)(M1.4x6)

(M1.4x7)

十字機械牙螺絲組(M1.4x3)(M1.4x5)(M1.4x6)

(M1.4x7)

207610 Machine Screws(M2x4.6)(M2x8.4)(M2x5)

(M2x2)

機械牙螺絲組(M2x4.6)(M2x8.4)(M2x5)(M2x2)

207615

Washer Pack (W1.4x2.5x0.4)(P1.4x2x3)

墊片包(W1.4x2.5x0.4)(P1.4x2x3)

207616

Washer Pack(W3.1x5.5x1.1-W3.1x4.6x1)

墊片包(W3.1x5.5x1.1-W3.1x4.6x1)

207700 Blade Support&Cable Tie with Touch

Fastener(for H255)

主翼支撐墊&魔術束帶包(H255用)

207750

Pinion Gear with Neck 15T(for 2.3mm shaft)

長頸馬達齒15T(孔徑2.3mm)

207751 Tail Rotor Belt(for H255 Series)

尾傳動皮帶(颶風 255系列用)

207953 Hurricane 255 Kit

颶風 255 Kit

207955 Hurricane 255 Super Combo

颶風 255 Super Combo