20

|

Introduction

Thank you for purchasing one for our products.

Before using the equipment you should carefully read

the instructions included in this manual.

It is also necessary to read all the safety regulations in the enclosed docu

-

ment „Safety instructions and maintenance“.

In order to get the best performance from the system and ensure that its

parts last as long as possible, you must strictly follow the usage instructions

and the maintenance regulations included in this manual. In the interest of

customers, you are recommended to have maintenance and, where nece

-

ssary, repairs carried out by the workshops of our service organisation, since

they have suitable equipment and specially trained personnel available. All

our machinery and systems are subject to continual development. We must

therefore reserve the right to modify their construction and properties.

Description

Machines 305, 405, 3500 and 4100 are professsional welding machines de

-

signed for MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding. It is

sources of welding current with flat characteristics. It concerns welding in

protection atmosphere of active and intact gases when added material is in

a form of „infinite“ wire supplied into the weld by the wire feeding. These

methods are very productive, especially for the welds of construction steel,

low steel, aluminium and its alloys.

The machines are designed as movable sets, differing from each other in

their efficiency. The source of welding current, wire supply and feed are in

one compact metal case with two fixed and two turning wheels.

Welding machines have been designed for welding of thin and thickness

materials for wires used from 0.6 to 1.2 mm. Standard equipment of ma

-

chines can be found in chapter „Equipment of welding machines“. Welding

machines confirm to all European Union and Czech Republic standards and

directives in force.

Contents

ENGLISH

INTRODUCTION ...................................................................................... 20

DESCRIPTION .......................................................................................... 20

TECHNICAL DATA ................................................................................... 20

TYPES OF MACHINES .............................................................................

21

INSTALLATION ........................................................................................

21

EQUIPMENT OF WELDING MACHINES ................................................

21

CONNECTION TO THE ELECTRICAL POWER SUPPLY ...........................

21

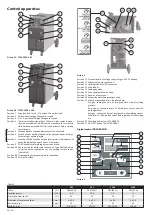

CONTROL APPARATUS ...........................................................................

22

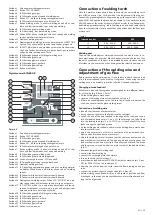

CONNECTION OF THE WELDING TORCH ............................................. 23

CONNECTION OF THE WELDING WIRE AND ADJUSTMENT

OF GAS FLOW ......................................................................................... 23

ADJUSTMENT OF WELDING PARAMETERS .......................................... 24

WELDING WORK CYCLES ....................................................................... 28

RATING PLATE SYMBOLS ....................................................................... 49

RECOMMENDED ADJUSTMENT OF WELDING PARAMETERS ............ 50

ELECTRICAL DIAGRAM .......................................................................... 54

LIST OF SPARE PARTS ............................................................................. 55

TROUBLE SHOOTING LIST ..................................................................... 61

WARRANTY CERTIFICATE ...................................................................... 66

Table 1

Technical data

305

405

3500

4100

Mains voltage 50/60 Hz

[ V ]

3 x 400

3 x 400

3 x 400

3 x 400

Welding current range

[ A ]

30 - 280

30 - 350

30 - 280

50 - 350

Output voltage settings

[ V ]

17 - 38

18 - 40

19.2 - 41.9

22 - 51

Regulation steps

-

20

40

20

40

Duty cycle

[ A ]

280 (30 %)

350 (30 %)

280 (40 %)

350 (35 %)

Duty cycle 60 %

[ A ]

260

300

270

280

Duty cycle 100 %

[ A ]

220

260

235

240

Mains current/input 60 %

[ A/kVA ]

12.3 / 8.6

15.3 / 10.6

14.8 / 10.6

17.3 / 12.8

Mains protection-slow, D

[ A ]

25

25

25

25

Winding

-

Cu

Cu

Cu / Al

Cu / Al

Wire feeder

-

2-roll

4-roll

4-roll

4-roll

Digital voltammeter

-

Yes

Yes

Yes

Yes

Standardly equiped roll

[ mm ]

1.0 - 1.2

1.0 - 1.2

1.0 - 1.2

1.0 - 1.2

Wire feed speed

[ m/min ]

0.5 - 20

0.5 - 20

0.5 - 20

0.5 - 20

Diameter of wire - Fe

- Al

- Tube wire

[ mm ]

0.6 - 1.2

0.8 - 1.2

0.8 - 1.2

0.6 - 1.2

1.0 - 1.2

0.8 - 1.2

0.6 - 1.2

0.8 - 1.2

0.8 - 1.2

0.6 - 1.2

1.0 - 1.2

0.8 - 1.2

Protection degree

-

IP 21S

IP 21S

IP 21S

IP 21S

Insulation class

-

F

F

F, H

F, H

Standards

-

EN 60974-1, EN 60974-5, EN 60974-10

Dimensions LxWxH

[ mm ]

806x490x822

806x490x822

902x510x890

902x510x890

Weight

[ kg ]

93

101

88

93

EN

Summary of Contents for 305

Page 22: ... 67 ...