© ANITA

MP04000EN_190301

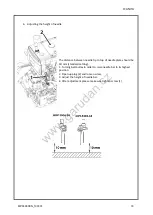

Setting up chain stitch looper:

When chain stitch looper moves to its utmost left

position, the distance between tip of chain stitch

looper and the center of chain stitch needle should

be 1,5 mm. Adjustment can be made by loosen

screw (1).

When changing the size of needle or when

looper. Please refer to Diagram 1.

1. Please open up back cover (1) of sewing machine.

2. Loosen screw (3) a little bit (Please do not loosen screw (3) completely).

3. Turning adjusting screw (2).

4. Turning toward (+) direction in order to obtain bigger movement. Turning toward (

order to obtain smaller movement.

5. After adjustment, please make sure tighten screw (3) and back cover (1).

When chain stitch looper moves to its utmost left

distance between tip of chain stitch

looper and the center of chain stitch needle should

be 1,5 mm. Adjustment can be made by loosen

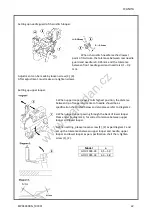

When tip of looper moves to the center of

chain stitch needle, the tolerance between

looper tip and needle grove should be

0 – 0,05 mm. Adjustment can be made by

loosen screw (1).

When changing the size of needle or when adjusting the front and rear movement amount of tip of

looper. Please refer to Diagram 1.

lease open up back cover (1) of sewing machine.

Loosen screw (3) a little bit (Please do not loosen screw (3) completely).

4. Turning toward (+) direction in order to obtain bigger movement. Turning toward (

order to obtain smaller movement.

5. After adjustment, please make sure tighten screw (3) and back cover (1).

21

When tip of looper moves to the center of

chain stitch needle, the tolerance between

tip and needle grove should be

0,05 mm. Adjustment can be made by

adjusting the front and rear movement amount of tip of

4. Turning toward (+) direction in order to obtain bigger movement. Turning toward (-) direction in

www.garudan.cz

Summary of Contents for GOV-1004-24

Page 6: ...ANITA MP04000EN_190301 6 3 MACHINE SETTINGS 1 Threading map w w w g a r u d a n c z...

Page 23: ...ANITA MP04000EN_190301 23 w w w g a r u d a n c z...

Page 24: ......

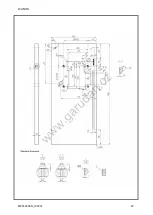

Page 34: ...ANITA MP04000EN_181213 4 1 HOUSING FRAME w w w g a r u d a n c z...

Page 36: ...ANITA MP04000EN_181213 6 2 OUT COVER FRAME 1 2 w w w g a r u d a n c z...

Page 38: ...MP04000EN_181213 2 OUT COVER FRAME 2 2 OUT COVER FRAME 2 2 ANITA 8 w w w g a r u d a n c z...

Page 40: ...ANITA MP04000EN_181213 10 3 OUT COVER FRAME 2 w w w g a r u d a n c z...

Page 42: ...ANITA MP04000EN_181213 12 4 THREE AUTOMATIC FRAME w w w g a r u d a n c z...

Page 44: ...ANITA MP04000EN_181213 14 5 MAIN SHAFT MECHANISM w w w g a r u d a n c z...

Page 46: ...ANITA MP04000EN_181213 16 6 THREAD TENSION MECHANISM w w w g a r u d a n c z...

Page 48: ...ANITA MP04000EN_181213 18 7 NEEDLE DRIVE MECHANISM 1 2 w w w g a r u d a n c z...

Page 52: ...ANITA MP04000EN_181213 22 8 NEEDLE DRIVE MECHANISM 2 w w w g a r u d a n c z...

Page 54: ...ANITA MP04000EN_181213 24 9 UPPER LOOPER DRIVE MECHANISM w w w g a r u d a n c z...

Page 56: ...ANITA MP04000EN_181213 26 10 LOWER LOOPER MECHANISM w w w g a r u d a n c z...

Page 58: ...ANITA MP04000EN_181213 28 11 CHAIN STITCH LOOPER MECHANISM w w w g a r u d a n c z...

Page 60: ...ANITA MP04000EN_181213 30 12 CAM ASSEMBLY w w w g a r u d a n c z...

Page 62: ...ANITA MP04000EN_181213 32 13 DIFFERENTIAL FEED ASSEMBLY 1 2 w w w g a r u d a n c z...

Page 66: ...ANITA MP04000EN_181213 36 14 DIFFERENTIAL FEED ASSEMBLY 2 w w w g a r u d a n c z...

Page 68: ...ANITA MP04000EN_181213 38 15 KNIFE DRIVE ASSEMBLY w w w g a r u d a n c z...

Page 70: ...ANITA MP04000EN_181213 40 16 PRESSER FOOT ASSEMBLY w w w g a r u d a n c z...

Page 72: ...ANITA MP04000EN_181213 42 17 THREAD TAKE UP AND THREADING FRAME w w w g a r u d a n c z...

Page 74: ...ANITA MP04000EN_181213 44 18 LUBRICATION ASSEMBLY w w w g a r u d a n c z...

Page 76: ...ANITA MP04000EN_181213 46 19 HR DEVICE w w w g a r u d a n c z...

Page 78: ...ANITA MP04000EN_181213 48 20 OIL TANK BRACKET w w w g a r u d a n c z...