ANITA ©

MP02300EN_170818

22

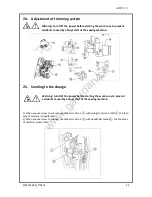

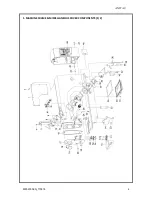

24.

Adjustment of trimming system

Warning: Turn OFF the power before starting the work so as to prevent

accidents caused by abrupt start of the sewing machine.

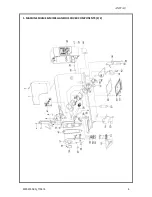

25.

Sending to the change

Warning: turn DFF the power before starting the work so as to prevent

accidents caused by abrupt start of the sewing machine.

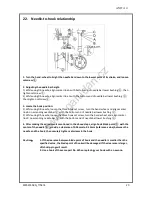

1) When you use screw to connect needle bar small rod ② with swing front crank shaft ①,the feed

way of machine is needle feed.

2) When you use screw to connect needle bar small rod ② with needle bar holder①, the feed way

of machine is lower feed

www.garudan.cz

Summary of Contents for GF-1107-147 MH

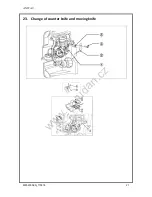

Page 21: ...ANITA MP02300EN_170818 21 23 Change of counter knife and moving knife w w w g a r u d a n c z ...

Page 28: ...ANITA MP02300EN_170818 w w w g a r u d a n c z ...

Page 38: ...ANITA MP02300EN_170818 8 2 MAIN SHAFT THREAD TEKE UP COVER COMPONENTS w w w g a r u d a n c z ...

Page 44: ...ANITA MP02300EN_170818 14 4 HANG LIFTER TENSION RELEASE COMPONENTS w w w g a r u d a n c z ...

Page 46: ...ANITA MP02300EN_170818 16 5 THE NEEDLE BAR SWING COMPONENTS w w w g a r u d a n c z ...

Page 48: ...ANITA MP02300EN_170818 18 6 FEED ADJUST MECHANISM COMPONENTS w w w g a r u d a n c z ...

Page 52: ...ANITA MP02300EN_170818 22 8 BOBBIN WINDER COMPONENTS w w w g a r u d a n c z ...

Page 54: ...ANITA MP02300EN_170818 24 9 AUTOMATIC REVERSE FEED COMPONENTS w w w g a r u d a n c z ...

Page 56: ...ANITA MP02300EN_170818 26 10 THREAD STAND COMPONENTS w w w g a r u d a n c z ...

Page 58: ...ANITA MP02300EN_170818 28 11 WIPER COMPONENTS w w w g a r u d a n c z ...

Page 64: ...ANITA MP02300EN_170818 34 13 OIL LUBRICATION COMPONENTS w w w g a r u d a n c z ...

Page 66: ...ANITA MP02300EN_170818 36 14 ACCESSORIE PART COMPONENTS w w w g a r u d a n c z ...

Page 68: ......