7.0 Maintenance

T-BA/ET-1250-0-GB-

10

-

11

17

7.0 Maintenance

7.1 Warranty

Please note that we accept no liability in the event of

failure to comply with the installation and operating

manual.

It should be noted that repairs on the rotary compres-

sors, respectively compressor vacuum pumps may

only be carried out by authorized workshops using ori-

ginal spare parts; failure to comply with this require-

ment will result in the warranty becoming void. A list of

our customer service stations is separately enclosed

with the order documentation.

7.2 Maintenance, maintenance schedule

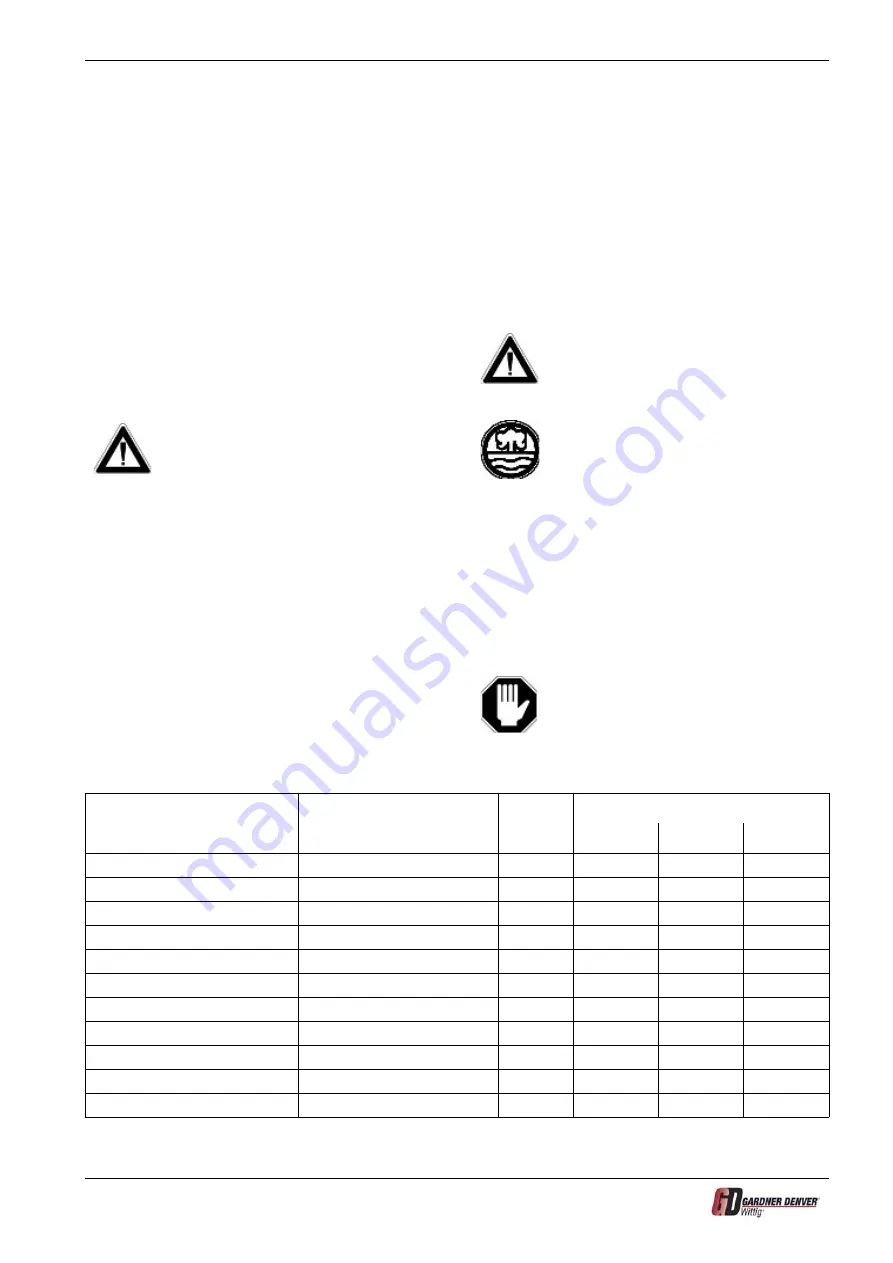

Please follow the safety notes on page 5

when carrying out maintenance and

inspection work.

Disturbances due to inadequate or improper mainte-

nance can incur very high repair costs and prolonged

machine downtime. Regular maintenance is thus

essential.

The operating safety and service life of the machine

depends primarily on proper maintenance.

The following table contains time, control and mainte-

nance information for normal use of the machine.

The stated maintenance periods are based on a daily

operating time of about 5 hours. The maintenance

period can be extended if the specified number of

operating hours is not achieved.

Due to the different operating conditions it is impossi-

ble to predict when the check up for wear, repairs,

maintenance and inspections will be required. A suita-

ble inspection routine needs to be specified in accor-

dance with your operating conditions.

Upon completing the work, the protective

devices must be properly reattached.

When removing oil, grease, solvents or

parts, e.g. filter cartridges, please com-

ply with the regulations for safeguarding

the environment.

7.2.1 Cooling

The cooling air requires a free passage.

Check the cooling air inlets and outlets every week

and clean away the adhering dirt and dust where nec-

essary.

For an optimum cooling effect, unrestric-

ted circulation of the air is essential. Fou-

ling reduces the cooling effect and can

cause the machine to overheat and fail.

Maintenance schedule

Maintenance points

Type of work

see

Maintenance periods

Chapter

1 week

1 month

3 months

Cooling air guide

check, clean

•

Compressor vacuum pump

clean

•

Vacuum filter

clean

•

Combination air filter check,

clean

•

Safety valve

check

•

Vent valve

check, clean

•

V-belt, belt tension

check, retighten

•

Oil tank

clean

•

Check valve

check

•

Vent valve

check, clean

7.2.8

•

Rotary slide valve

Check for wear (intake flange)

•