11

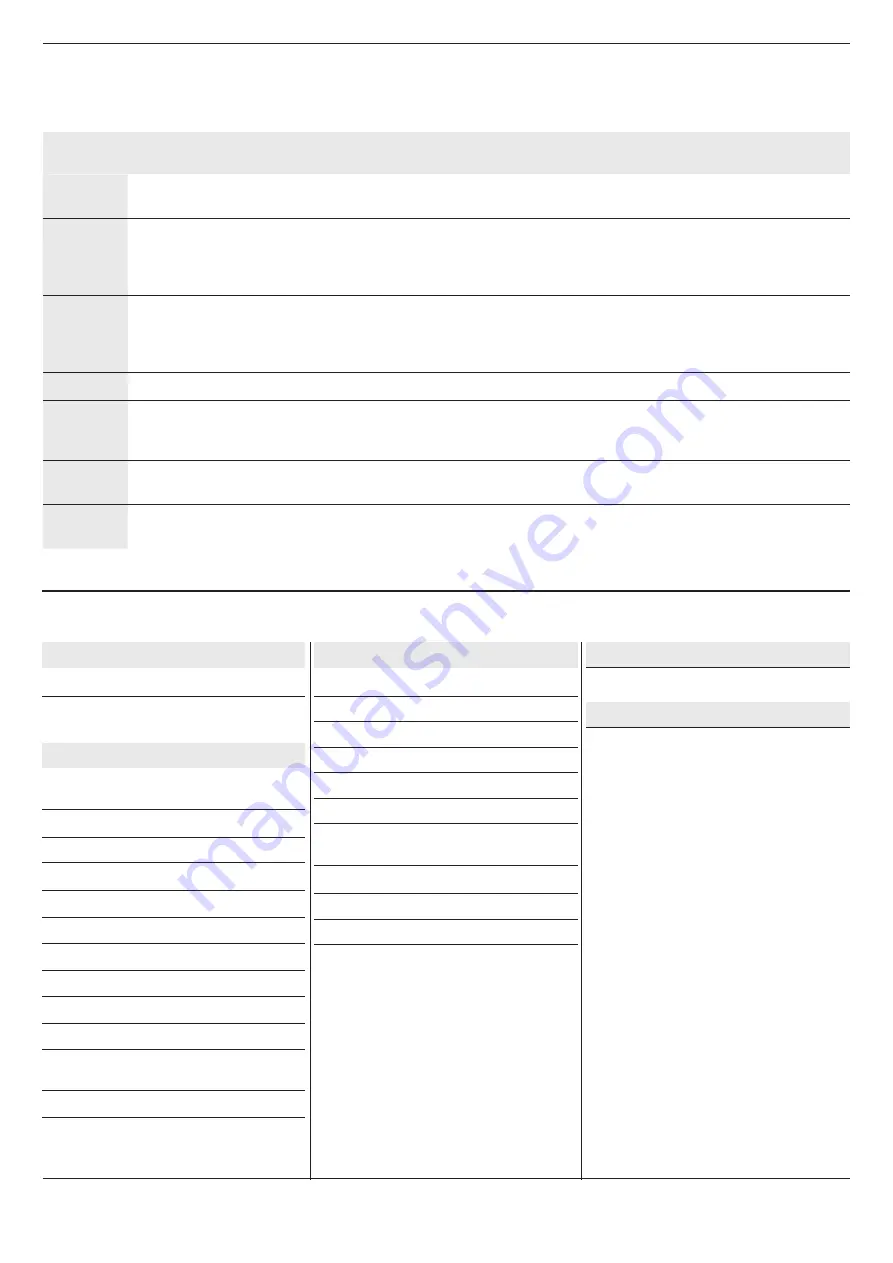

Setting process

1

Turn OFF the power and connect the encoder and all safety equipment.

The controller memorises the encoder type by power-up.

2

Set DIP10 in ON position and turn the power ON. Activate setting by pressing OPEN + STOP for about 10 sec until the

red LED FAIL (PCB) starts with 2 short flashes

ATTENTION: Switching DIP10 to ON position and back to OFF will reset to mechanical standard with ONLY PNE edge

type.

3

First press the CLOSE button to the desired down limit position.

Note: if door is moving in the wrong direction the 2 phases on the mains connection must be interchanged.

(Alternatively choose the special phases interchange function by pressing OPEN + STOP for 20 sec. - Yellow LED SPE-

ED/SER confirming with 1 sec.)

4

Press STOP to set the down limit position. Yellow LED SPEED/SER confirming with 1 sec

5

Press OPEN to the desired UP limit position.

By open position you can adjust the UP limit position finely by running OPEN and CLOSE, but first operation must be in

OPEN direction for minimum 2 sec.

6

Press STOP button to save the UP limit position, encoder direction,

edge type and photo

Yellow LED SPEED/SER confirming with 1 sec

7

Limits are now adjusted and edge type and photo circuit are set.

Check that the safety edge and photo functions are working as expected.

Yellow LED CONF./SER. (PCB)

Fixed light

Service needed (open

counts reached)

1 sec. flash

Confirming setting process

Green LED POWER (PCB)

Fixed light

The controller is powed

Red LED CIRCUIT ERROR (PCB)

Fixed light

PCB circuit error fail

Red LED FAIL (PCB)

Fixed light

If Photo or Edge is activated

when CLOSE pushbutton is

activated

1 short flashes

No answer from encoder.

Check RS485

1 long flash

Auto close setting active

2 short flashes

Limits, edge and photo not

learned

2 long flashes

Force control (speed) not

learned

3 long flashes

Door stopped by force control

4 short flashes

Calculation failure (e.g. both

limits the same)

4 long flashes

Door stopped by runtime

5 long flashes

Door stopped by force control

wear

6 long flashes

Tacho failure – pulses missing

7 short flashes

Encoder position out of learned

area. (Reset by power up or

resetting)

8 short flashes

Kostal encoder – Power

failure.

Continues long

flashes

Fail state PNE edge monito-

ring. Check impuls by floor

missing.

Yellow LED STOP (PCB)

Fixed light

Stop activated or both limits

are active

1 long flash

Safety chain activated

2 long flashes

Photo – safety test failed.

3 long flashes

Safety edge – safety test failed.

4 long flashes

Stop circuit – safety test failed.

5 long flashes

Safety chain – safety test failed

6 long flashes

EEPROM failure. Elec. Counter

or position counter by force

control

7 long flashes

EEPROM failure. Powerup

failure

8 long flashes

Welded contactor fail

9 long flashes

Internal watchdog timeout.

10 long flashes

Main processor crystal fail

5.2 LED GUIDANCE

5.1 PROGRAMMING WITH ELECTRONIC LIMIT SWITCH

ATTENTION

: to let the safeties work, these must be connected

before

starting the control unit setup.