15

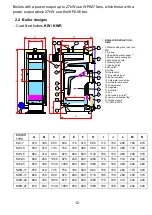

3.2 Setting up the boiler

The boiler does not require a foundation. The boiler should be placed in

a way that allows access for proper maintenance (cleaning the boiler -

access to the top and bottom {for KWRU boilers} cleaning hatch).

Installation of the boiler should be performed in accordance with PN-

87/B-024411. The room where the boiler is to be situated should have at

least two 140x140mm vents (gravitational ventilation), with one situated

150mm above floor level and the other near the ceiling. The boiler room

doors should open to the outside and be made of fireproof materials. The

room should be dry with a sewer grate installed in the floor, water supply and

an earthed electrical installation.

Lighting for the front side of the boiler is to be provided.

The socket for connecting the controller should have a safety contact

and be placed at a safe distance from sources of heat and water.

The boiler should be placed in the boiler room, so that it is away from

easily flammable items, fuel should be fenced off.

3.3 Connecting the boiler

The right height and diameter of the chimney have a significant impact on

the proper operation of the boiler. Check that the chimney is made in

accordance with the

PN-91/B-02413 standard.

The flue is to be connected to

the chimney through a connection made of sheet metal, which must be

mounted onto the flue outlet, fixed in the chimney and sealed. The connection

(max length of 400mm) should rise slightly at an angle of at least -10% and

have a cleaning hole. Under the connection, the chimney wall should have a

tightly sealed cleaning hole to allow easy access for cleaning and removal of

accumulated soot and ash.

Providing water for the central heating from the

water supply network is to be done using a downward facing valve installed

onto a T-connector mounted on the cold water pipe.

INSTALL BOILER SO THAT IT CAN BE DISCONNECTED FROM THE

SYSTEM!

2000

200

200 -

for KW, KWR

600 -

for KWRU

access to the bottom

cleaning hatch

200 -

for

KW, KWR

600 -

for KWRU

access

to cleaning

hatch

Summary of Contents for KW-10

Page 2: ...2 www galmet com pl ...

Page 3: ...3 ...

Page 4: ...4 ...

Page 5: ...5 ...

Page 23: ...23 ...