3

UT66000806 - 02

UTN

All copying, even partial, of this manual is strictly forbidden

3

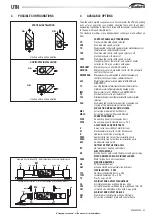

POSSIBLE CONFIGURATIONS

VERTICAL INSTALLATION

Heating and cooling operation

AB

AA

HORIZONTAL INSTALLATION

Heating and cooling operation

AA

AB

4

AVAILABLE OPTIONS

The wide and complete range of accessories completes the UTN air handling

units as far as operation is concerned, adapting these units to any plant-

engineering requirements, from the solution with rectangular section channels

to the one with round flexible ducts.

The standard machines are supplied without control panel and without air

filter.

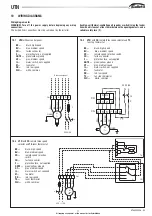

CONTROL PANELS AND THERMOSTATS

CD

Flush wall-mounted speed selector

CDE

Wall-mounted speed selector

TD

Wall-mounted control with speed selector, electromechanical

thermostat and summer/winter selector

TDC

Wall-mounted control with speed selector and

electromechanical thermostat

TD4T

Wall-mounted control with speed selector,

electromechanical thermostat and summer winter

selector for 2/4 pipe systems with valves

MICRONET

Microprocessor control ERGO solution

MICROD

Microprocessor wall-mounted control for the automatic

control of the fan-coil

MICROPROD

Microprocessor wall-mounted control for the automatic

control of the fan-coil, valves and electric heater

SW

Water temperature electronic probe for MICROD and

MICROPROD

TC

Fan stop thermostat: electromechanical thermostat for

minimum water temperature during heating mode

IPM

Power interface for MICROD and MICROPROD

TA

Electromechanical room thermostat

TA2

Electromechanical room thermostat with summer/winter

selection

CSD

Wall-mounted control for proportional opening and

closing of the motor driven air intake louver

AIR SUCTION MODULES WITH FILTERS

MAF

Air suction module with flat filter G2

MAFO

Air suction module with waved filter G4

CONNECTION PANELS

PCOC

Connecting panel to rectangular ducts

PCOF

Connecting panel to flexible ducts

φ

200

3-WAY VALVES AND DRIP TRAYS

V

3 way valve (possibility of motor driven)

M

Electrothermal motor for motor driven valve

R

Hydraulic connection mounting kit

VRCV

Auxiliary drip tray for vertical installation units

VRCH

Auxiliary drip tray for horizontal installation units

KSC

Condensate removal kit

HOT WATER POST HEATING COIL

BP

Hot water post heating coil module

ELECTRIC HEATERS

RE

Electric heater, with safety thermostat and power relay

MOTOR DRIVEN FRESH AIR INTAKE LOUVER

PA90

Motor driven fresh air intake louver

VIBRATION DAMPERS

GA

PVC vibration damper

GAT

Silicone cloth heat proof vibration dampers

FLEXIBLE DUCTS - CAPS

TFA

Not insulated flexible ducts,

φ

200

TFM

Insulated flexible ducts,

φ

200

TP

Plastic caps

φ

200

AIR INLET AND OUTLET PLENUM BOX

CA

Air inlet plenum box with double row grille

CAF

Air inlet plenum box with double row grille and filter G2

CM

Insulated air outlet plenum box with 2 way grille

AIR INLET AND OUTLET GRILLES

GM

Aluminium air outlet grille with counterframe

GR

Air suction aluminium grille with counterframe

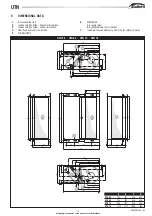

UTN

PCOF

MAF

MAFO

PCOF

TFA

CA

CAF

TFM

CM

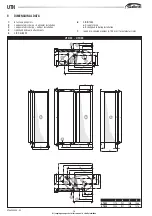

UTN

MAF

MAFO

GA

GAT

PCOC

PCOC

GR

GM

G90

GA

GAT

Example of installation UTN - Air distribution with circular flexible ducts

Example of installation UTN - Air distribution with rectangular ducts