GAR CUT (V. INDUSTRIAL). Instructions Manual

16

CHAPTER 2. TRANSPORT AND INSTALLATION.

Knocks and sudden movements must be avoided when transporting the equipment. The equipment will

always be transported vertically. The packaging must be protected from water.

The GAR CUT (

V. Industrial

) equipment has lifting eyes. Preferably use this system.

IF A TRANSPALLET IS USED FOR LIFTING MAKE SURE THE EQUIPMENT IS STABLE.

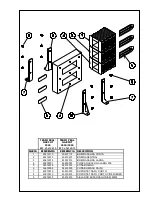

Wheels assembling.

2.1 ELECTRICAL AND PNEUMATIC INSTALLATION.

The location must meet the following requirements:

- Place: Dry and ventilated, far enough away from the cutting area in order to prevent the metal dust caused

by the cutting process from getting into the equipment.

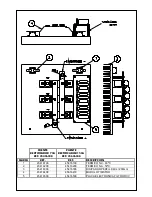

Electrical installation. Magnetothermal switch.

CUT 2500

CUT 4000/5000

40 A -230V 25 A -400V 63 A -230V 40 A-400V

Power supply hose (RVK-1KV).

CUT 2500

CUT 4000/5000

Length

230 V

400 V

230 V

400 V

10 m

6 mm

2

6 mm

2

10 mm

2

10 mm

2

15-20 m

10 mm

2

6 mm

2

16 mm

2

10 mm

2

The standard equipment leave the factory with the voltage selector at

400 V, in order to protect it against negligence in the connection.

230 V:

1º. Place screw T in position 2.

2º. To connect the equipment place handle in 230 V. position

Pneumatic installation: Minimum capacity of the installation 250 l/min - 6 bar.

The pneumatic intake can be carried out directly from the compressed air circuit, although it is

recommendable, if the air contains a considerable amount of humidity or oil, for a gas pre-heater to be fitted

in the input. Thus we will avoid arc ignition failures as well as premature wear of the consumable elements

(electrode and nozzle).

Pos. 1

400 V

T

Pos. 2

230 V

1º

2º

ROTATION

WHEEL

FIXED

WHEEL

DO NOT FORGET

TO FIT THE

EARTH

CONNECTION

INTO THE PLUG.