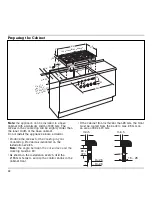

Replacing the main burner nozzles of the

normal burner and large burner

•

Detach the safety spring on the supply lines.

Leave the electrode connected. Unscrew the

burners from the trough (Torx T20) and pull off the

burner from both supply lines.

• Carefully pull off both main nozzles together with

the O-ring by hand.

• Check whether the O-rings of the new nozzle

seats are fitted correctly. Fully push nozzles onto

the supply lines.

Note:

do not bend supply lines.

• Push the burners onto the supply lines.

Push the safety springs back on.

• Screw the burners back on the trough.

• Loosen the locking screw and adjust the air

regulation bush according to the nozzle table.

Tighten the locking screw.

28

See table on page 17-19

for details of nozzle settings.

outer main nozzle

inner main nozzle

Summary of Contents for KG491110

Page 1: ...Operation Maintenance and Installation Manual KG 491 Gas Cooker...

Page 2: ......

Page 27: ...25...