Pitch Diameter Gage Operation Manual

Models MRP 1500/2500/3500

Copyright © 2018 Gagemaker. All rights reserved

56

MRP Accuracy Measurement Factors

Thread Addendum Measurements

Accurate MRP measurements are based on positioning the pivot shoe on the crest cone of the

thread at a prescribed distance from the face of the connector. If the distance from the pitch line

to the crest cone is accurate, then readings taken from at the crest cone directly reflect the

accuracy of the pitch diameter.

Problems occur when the threading process pushes a thread flank back, to decrease standoff of

a ring or plug. When the flanks are relocated, the distance from the pitch line to the crest is

changed.

Thread Addendum

is the change in the distance from the pitch line to the crest cone.

Changes in thread addendum affect the relationship of measurements taken with the MRP gage

and measurements taken with ring and plug gages.

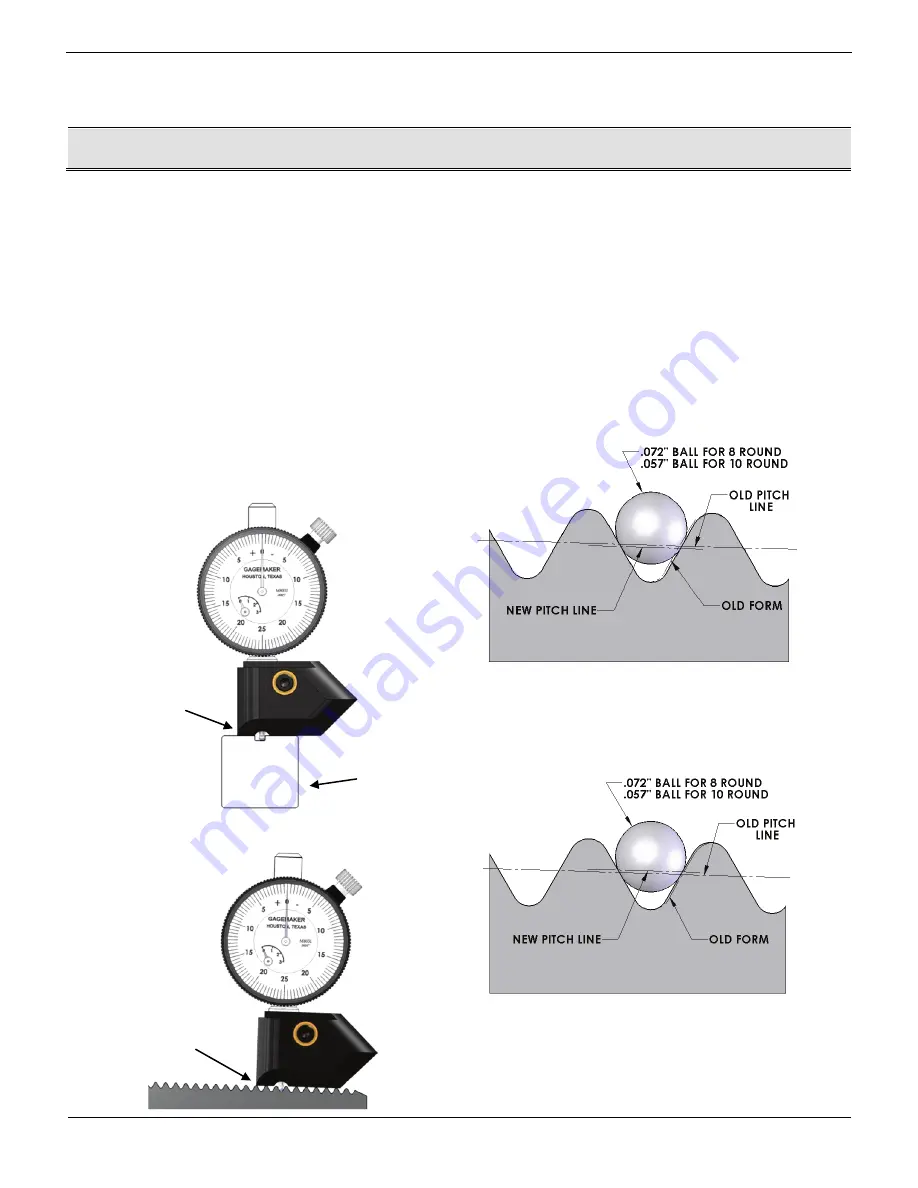

The diagrams below describe how plus and minus addendum is detected and how to compensate

for its effect on the readings of the MRP gage.

Plus Addendum – Wide Groove – Large Reading

Mating part will have less standoff

P.D. Correction for Plus Addendum:

Pin = Subtract 2 times deviation from P.D.

Box = Add 2 times deviation to P.D.

Minus Addendum – Narrow Groove – Small Reading

Mating part will have more standoff

P.D. Correction for Minus Addendum:

Pin = Add 2 times deviation to P.D.

Box = Subtract 2 times deviation from P.D.

Setting Standard

Seat the contact point into

the standard’s groove

Rest the gage on

the thread crests

Zero the indicator while the gage (TA-3002) is

on the standard (TAS-1014)

TAS-1014