5.6 AUTO-TUNE

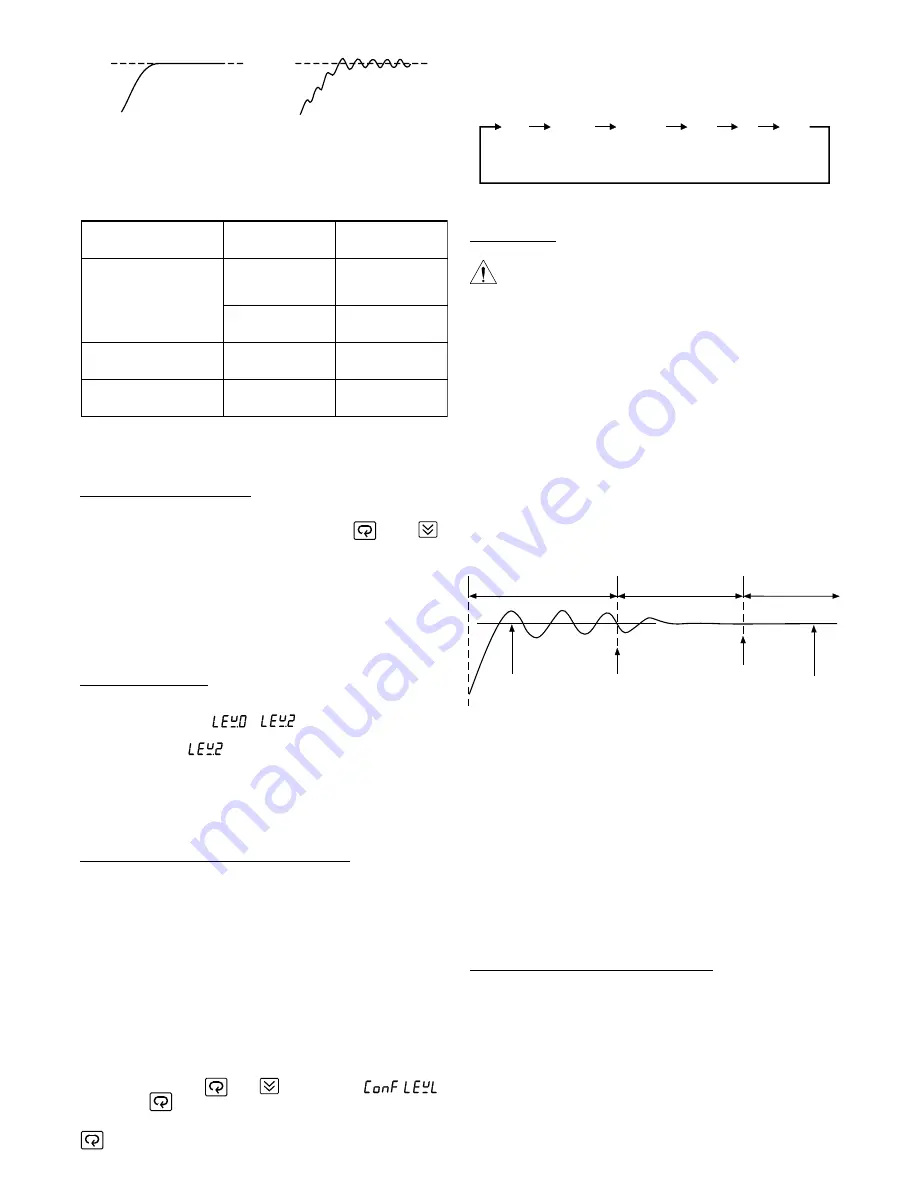

The process is tuned at setpoint. The process will oscillate about

the setpoint during auto-tune. Set a setpoint to a lower value if overshoot

beyond the normal process value is likely to cause damage.

The auto-tune program is applied during:

* Initial set-up

* The setpoint is changed substantially from the previous auto-tune

* The control result is unsatsifactory

The auto-tune procedures:

* To ensure that all parameters are configured correctly.

* To ensure that PB is not zero because that ON-OFF control is not allowable

to perform auto-tune.

* Set the setpoint to the normal operating process value ( or to a lower

value if overshoot beyond the normal process value is likely to cause

damage) and use normal load conditions.

* Press and hold both up and down keys for 3.2 seconds then release

together. The display is flashing during execution of auto-tune

program.

Auto-tune " teaches " the controller the main characteristics of the process.

It " learns" by cycling the output on and off. The results are measured and

used to calculate optimum PID values which are automatically entered in

nonvolatile memory.

During the second period of auto-tune the controller performs PID control

to verify the results and finally an OFST value is obtained and entered in

the memory.

To stop the auto-tune, press both up and down key then release together,

the display will stop to flash. But if the controller has entered in the

verifying period, the display will continue to flash until auto-tune is finished.

5.5.5 Configure Security Levels of Parameters

The user of the controller may often complain that the operation is so

complicated, most of parameters are unused for them and it takes long time

to get a parameter to access. You will no longer worry about this. One of

the versatile functions of this controller is that the security level for each

parameter can be redefined arbitrarily. One of four levels (Level 0, Level

1, Level 2 and Level 3) can be assigned to any parameter. The parameters

with lower level will be displayed before those parameters with higher

level as one performs scroll key. Furthermore, the level 3 parameters will

never be displayed on the front panel. Hence the user can assign level 3

to those unused parameters and assign level 0 to those most frequently

used parameters according to his requirements. Then the unused

parameter will never appear on the display to avoid confusion and the

display sequence of parameters is reconfigured.

To configure level for each parameter one can follow the flow chart in

section 6.4 by pressing and keys to reach ,

then perform key to get the desired parameter. The display indicates

the level of the parameter. Now one can change the level value for that

parameter by using up key or down key. Finally press and hold

3.2 seconds or longer, now the new level value is entered. If the

level value is unchanged the above operation for entering can be omitted.

For example: If ASP1, RAMP are configured as level 0, PB, TI, TD are

configured as leve 1, and the other parameters are configured as level 3,

the scrolling sequence of parameters will be as follows:

5.7 TUNING THE CONTROLLER MANUALLY

* To ensure that all parameters are configured correctly

* Set PB to zero. Set HYST to the smallest ( 0 °C or 0.1 °F )

* Set the setpoint to the normal operating process value ( or to a lower

value if overshoot beyond the normal process value is likely to cause

damage) and use normal load conditions.

* Switch on the power supply to the heater. Under these conditions, the

process value will oscillate about the setpoint and the following

parameters should be noted:

(1) The peak to peak variation (P) of the first cycle in °C or °F ( i.e. the

difference between the highest value of the first overshoot and the

lowest value of the first undershoot ).

Normal Cycle time

Cycle time too long

(oscillates)

The follow table provides cycle time recommendations to avoid premature

relay failure:

Note: For an ON-OFF control ( by setting PB = 0) the cycle time selection

may be ignored.

Output Device

(OUT1 or Cooling Output)

Cycle Time

( CYC or CCYC )

Load ( resistive)

Relay

20 sec or more

recommended

10 sec. minimum

2A / 250VAC

or contactor

5 sec. minimum

1A / 250VAC

Solid State Relay Drive

1- 3 sec.

SSR

Linear Current / Voltage

0.1 sec.

Phase control module

5.5.3 FAIL-SAFE Configuration

FAIL-SAFE is a Tool Program used to define an ON or OFF status of failure

for Output 1 (OUT1), Alarm 1 Output (ALM1). Press and ,

then release both keys until FAIL-SAFE is viewed in the display windows.

Then press scroll key to obtain the desired output which is shown in the

display. Now press and hold up or down key to change the status which

is shown in the display. Note that if the desired value is different from the

original one, a long scroll (pressing scroll key 3.2 sec.) has to be operated

to enter the new value before proceeding to the next Tool Parameter . If

the FAIL-SAFE status is not critical for a process as the controller fails, the

configuration of this section can be omitted.

5.5.4 LOCK Parameter

According to the flow chart shown in section 6.4, one can reach LOCK

PARA and obtain LEVEL ( ~ ) which is shown in the display

and the Lock status ( LOCK or FREE ) is shown in the display. For example,

if we select LOCK for , and press scroll key 3.2 seconds to enter the

selection, then all the parameters configured in level 2 can not be changed.

A LOCK message will be indicated in display if one attemps to change a

locked (protected) parameter.

PID+FUZZY

Verifying period

PID Control

Teaching Period

ON-OFF Control

Setpoint

Value

PB,TI,TD

Obtained

Auto-tune

finished

OFST Value

Obtained

Process

Value

SV

ASP1

RAMP

PB

TI

TD

Page 8