User’s Manual for FD556 Digital 2-Phase Stepper Driver

User’s Manual for FD556 Digital 2-Phase Stepper Driver

5 6

3.

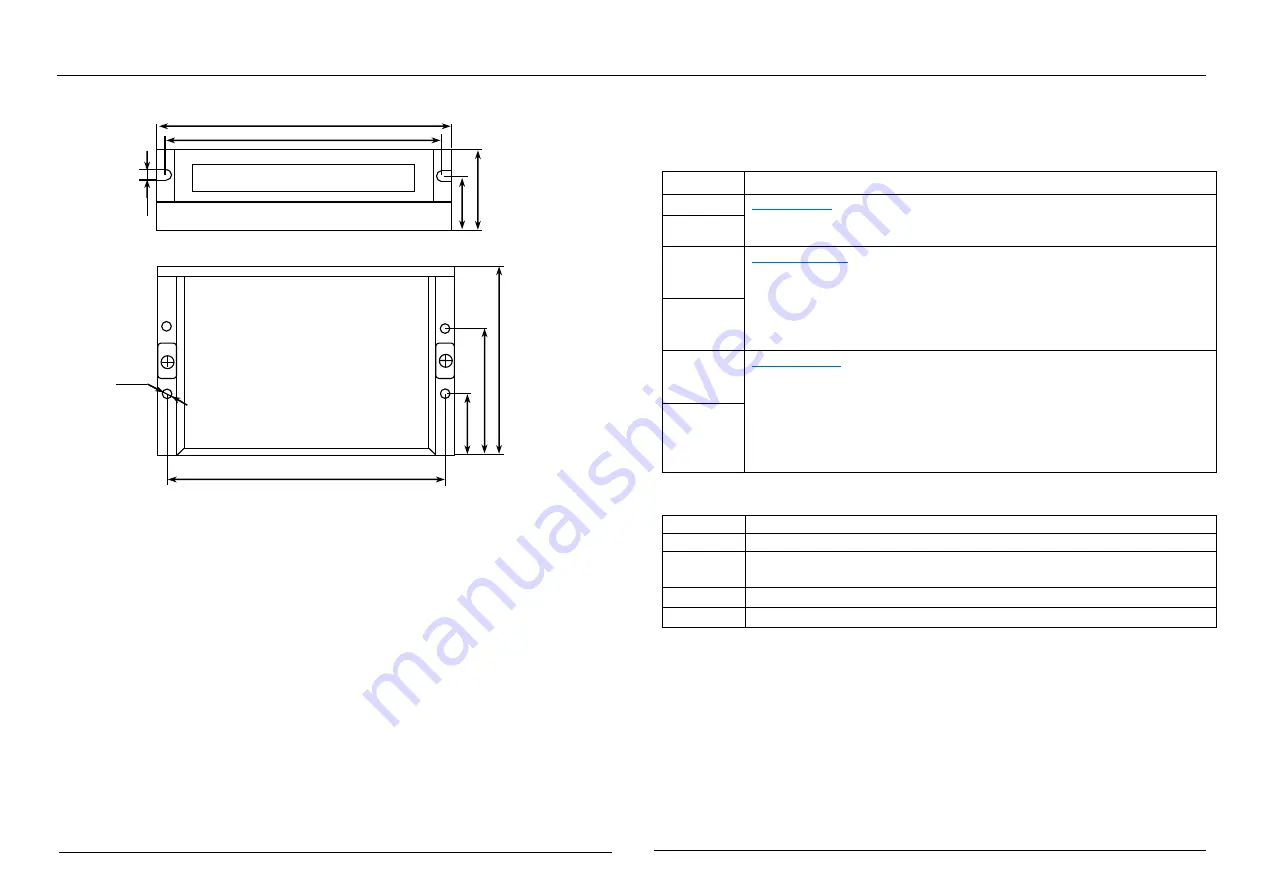

Mechanical Dimensions (unit: mm, 1 inch = 25.4 mm)

Figure 1: Mechanical dimensions

*

Recommended to use side mounting for better heat dissipation, When designing

the installation size, pay attention to the terminal size and wiring.

4. Elimination of Heat

1

)

Driver’s reliable working temperature should be <60

℃

, and motor working

temperature should be <80

℃

(176

℉

);

2

)

It is recommended to use automatic idle-current mode, namely current

automatically reduce to 50% when motor stops, so as to reduce driver heating and

motor heating;

3

)

It is recommended to mount the driver vertically to maximize heat sink area. Use

forced cooling method to cool the system if necessary, Ensure that the drives

operation in a reliable operating temperature range.

Ⅲ

.Pin Assignment and Description

1. Interface description

1

)

Control Signal Connector

Signal

Functions Details

PUL+

Pulse signal: This input represents pulse signal, each rising edge active,

4.5~28Vdc when PUL-HIGH, 0~0.5V when PUL-LOW, For reliable

response, pulse width should be longer than 1.5μs.

PUL-

DIR+

Direction signal: this signal has low/high voltage levels, representing two

directions of motor rotation; For reliable motion response, DIR signal

should be ahead of PUL signal by 2μs at least. 4.5V-28Vdc when

DIR-HIGH, 0-0.5V when DIR-LOW. Please note that rotation direction is

also related to motor-driver wiring match. Exchanging the connection of

two wires for a coil to the driver will reverse motion direction.

DIR-

ENA+

Enable signal: This signal is used for enabling/disabling the driver. High

level for enabling the driver and low level for disabling the driver. When

ENA-HIGH is connected to 4.5V-28Vdc, ENA-LOW is connected to

0-0.5V (or Internal optical coupling is conducted), the driver will cut off

the current of each phase of the motor to make the motor in a free state,

step pulses are not responded at this time. Usually left

unconnected

(enabled)

.

ENA-

2

)

Power Connector Configurations

Signal

Functions Details

GND

Power Ground.

+Vdc

Power supply, +24V~ +50Vdc Including voltage fluctuation and EMF

voltage, Recommended 36Vdc supply.

A+

、

A-

Motor coil A (leads A+ and A-)

B+

、

B-

Motor coil B (leads B+ and B-)

3

)

RS232/RS485 Communication Port

Special RS232 cable (Prohibition of charging plug) designed to setup communication

between the drive and PC-based configuration & tuning software ProTuner. The PC

software is used to configure the peak current, microstep, active level, current loop

parameters and the driver function, and so on.

118

112

34

112

22.

5

4.

5

4-

Ф

3.5

75.

5

25.

3

47.

8