10

U41243-J-Z156-1-76

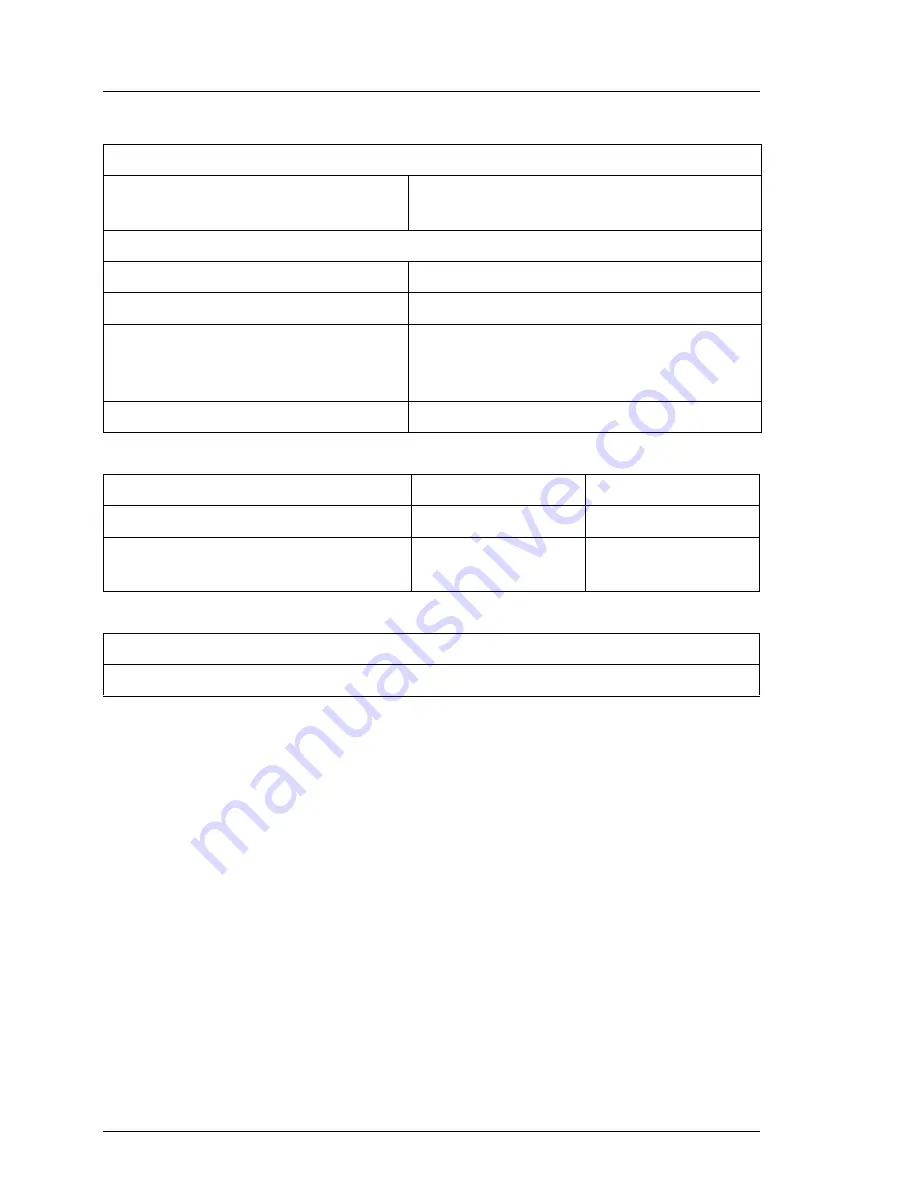

Technical data

Introduction

Standards

Product safety and ergonomics

IEC 60950 (DIN EN 60950), UL 1950,

CSA 950, NEMKO

Electromagnetic compatibility

Interference emission

EN 55022, Class A; FCC part 15, Class A

Interference immunity

EN 50082-1

CE certification

Low voltage directive

LVD 73/23/EEC

EMC Directive 89/336/EEC

Certification

GS, CSA NRTL/C, CB Certificate

Noise level (ISO 9296)

Operation

Idle

Sound power level (L

WAd

)

max. 5,5 B

max. 4,8 B

Operating sound

pressure level (L

pAm

)

max. 43 dB(A)

max. 32 dB(A)

Maintenance surfaces and ventilation clearances

Depends on 19" rack