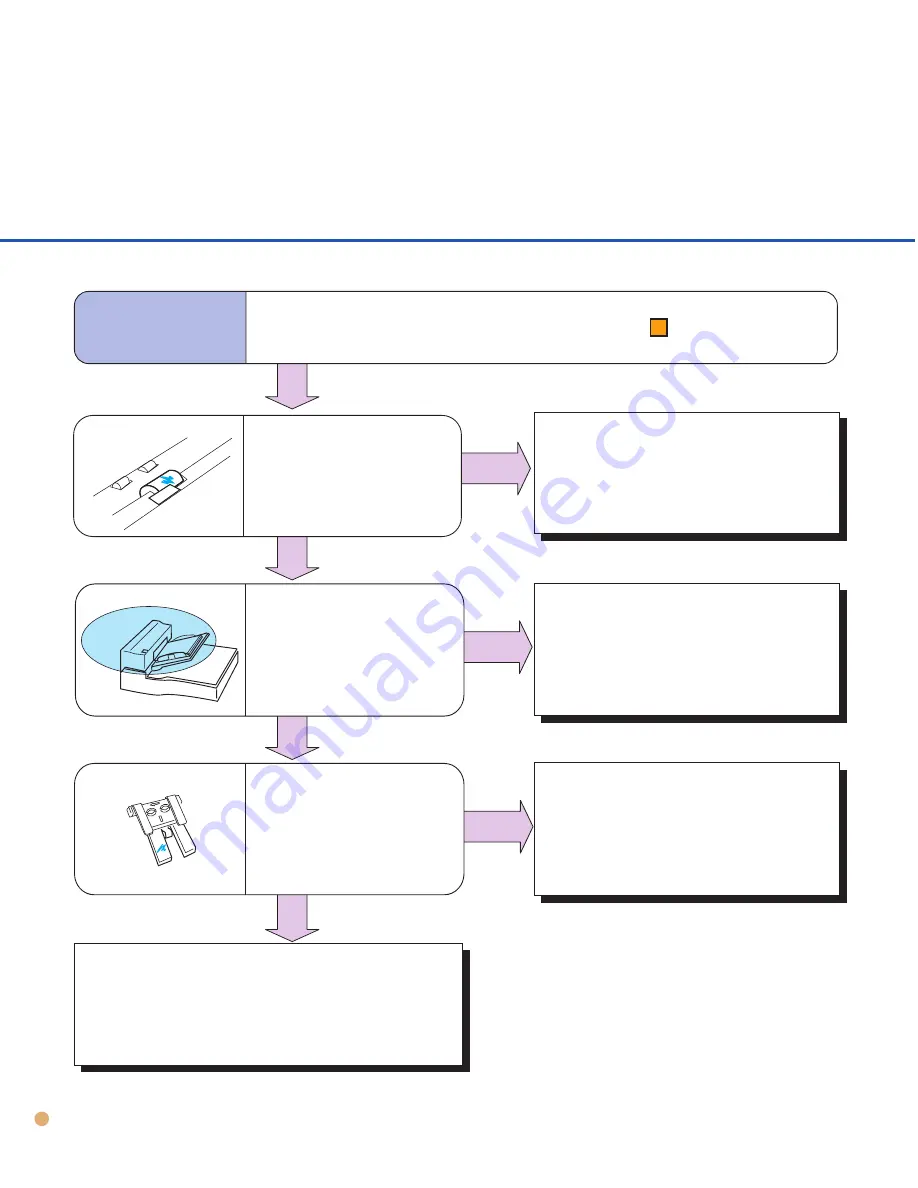

Symptom

7

Is the pick roller dirty?

“Check” lamp blinks at 4 seconds intervals.

NO

YES

Flatten the curl or use the

flatbed to read the document.

NO

Check

5-10

Are documents under

specification?

(See p5-11)

YES

YES

Is the Pad ASY dirty or

worn out?

Clean or replace the Pad ASY.

(See p3-4, p3-5, p4-2)

Contact manufacturer’s authorized

service center.

Clean the pick roller.

NO