Chapter 1 Scanner Overview

22

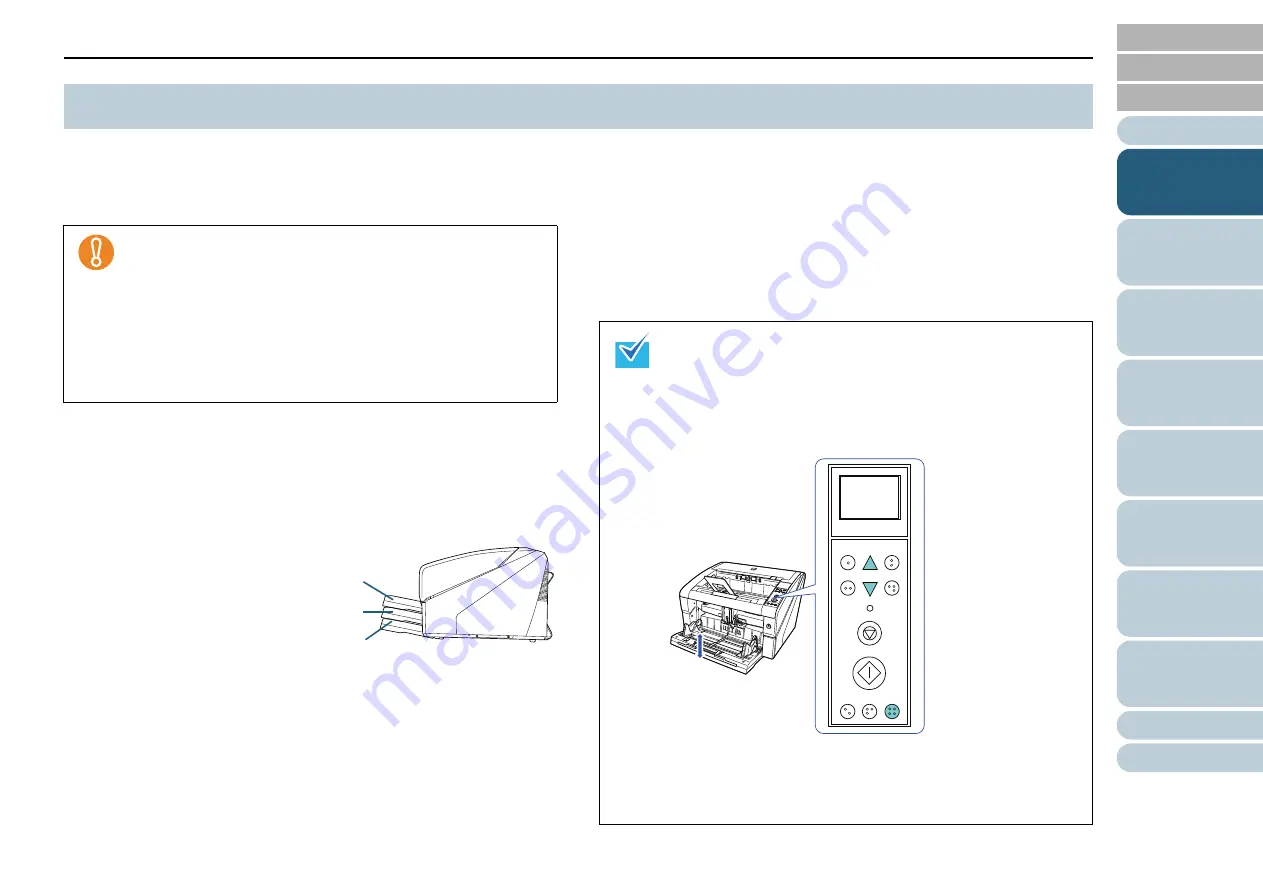

If there are only a few documents, you can set the hopper to a

higher position and shorten the time to get to the feeding

position.

This function is only available when [Ready] is displayed on

the operator panel LCD.

The hopper level can be set for three different capacities.

*1: For documents with a paper weight of 80 g/m

2

(20 lb).

The capacity varies depending on the paper weight of the document.

For more details, refer to

"2.2 Documents for Scanning" (page 37)

.

Use the operator panel to adjust the height of the hopper.

Configure by selecting [10: Hopper Level] in the [Main Menu]

of the operator panel.

For more details about the settings, refer to

When the scanner has just been powered on, it is set to the [4:

Lower] position.

1.7 Setting the Loading Capacity of the Hopper

To avoid the risk of jamming your fingers, do not touch the

hopper while it is moving up/down.

Do not place anything on top of the hopper while it is

moving. The scanner may be damaged if any object is

caught inside.

To avoid any contact that may damage the scanner, do not

place anything beneath the hopper.

Do not adjust the hopper height from the operator panel

when the hopper is closed, as it may damage the hopper.

Upper:

A maximum of 100

sheets (*1) can be

loaded.

Middle:

A maximum of 300

sheets (*1) can be

loaded.

Lower:

A maximum of 500

sheets (*1) can be

loaded.

Lower

Middle

Upper

[Hopper Level] can also be displayed by shortcut key. To

display the [Hopper Level] screen by shortcut key, press the

[Eject] button and either [

] or [

] button at the same time

when [Ready] is displayed. Change the hopper level by using

the [

] or [

] button in [Hopper Level]. Note that the [Hopper

Level] screen is not displayed unless the two buttons are

pressed simultaneously.

When [Hopper Level] is displayed by shortcut key, the screen

returns to [Ready] after a certain period of time. This period of

time can be configured in [18: Operation Panel Timeout] of the

operator panel.

Function

/Enter

Check

Menu

Scan

Stop

Eject

Counter

Reset

iMFF

Send to

/Pause

Clear

/Back