TROUBLE-SHOOTING

7-10

User's Manual

Printer Failures

A user cannot generally resolve a problem involving defective printer

hardware. On detecting a fatal error, the printer will:

• Stop printing

• Beep four times

• Turn the ONLINE indicator off

• Blink the PAPER OUT indicator (with a FONT indicator lit

indicating the error type).

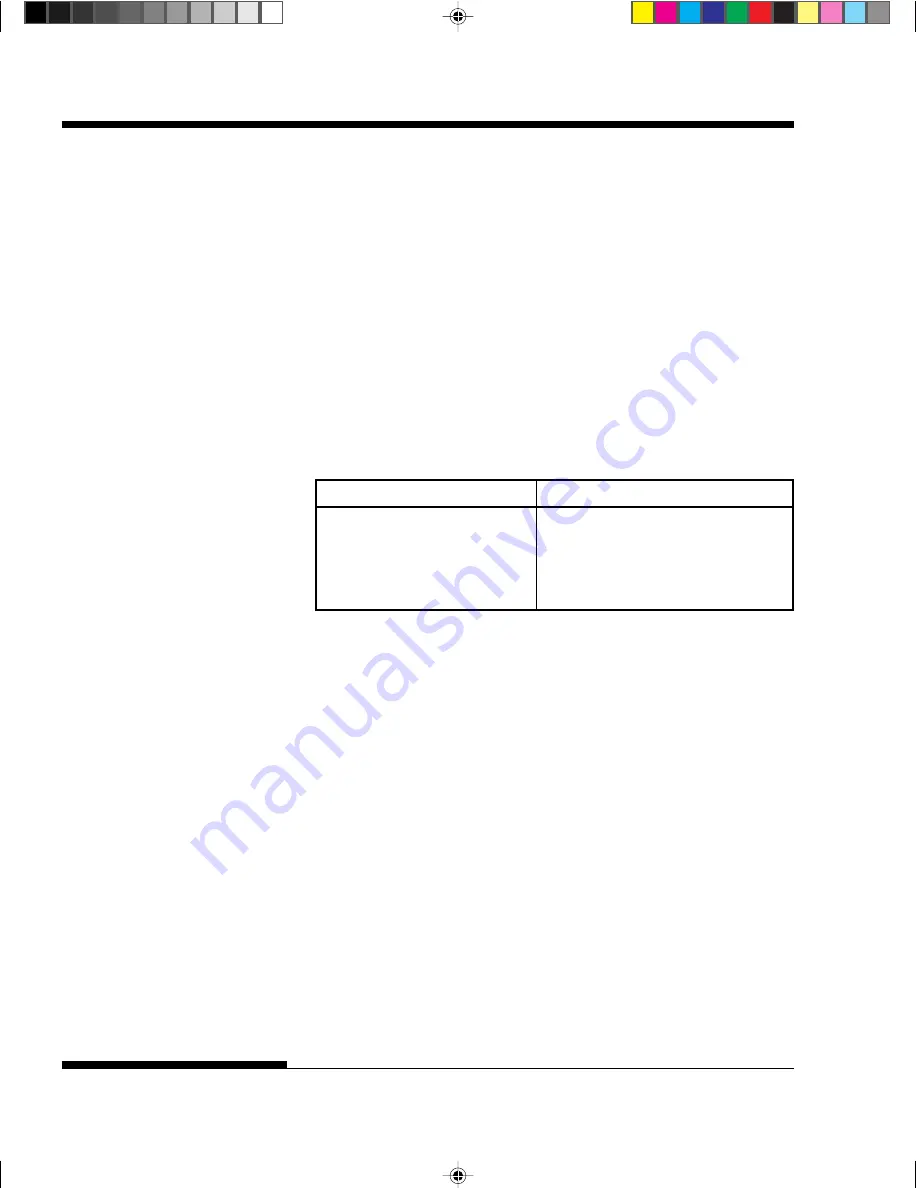

Table 7.4 Printer Failures

Error

FONT indicators lit

+34 V undervoltage error

COUR10

Left end sensor error

PRESTG12

Overload printing error

COMP17

RAM error

Bold PS

The following errors cause the printer to turn off the power:

• Print head error

• Space motor error

• Line feed motor error

• +34 V overvoltage error

No error condition is displayed if any of these errors occurs.

Turn the printer off and back on, then rerun the same job to check if

the error was transient. If the error recurs, contact your dealer.

#07 Chapter 7

2000.09.20, 2:40 PM

10

Summary of Contents for DL-3800

Page 1: ... 00 Frontcvr 2000 09 20 1 55 PM 1 ...

Page 16: ...User s Manual xiv 00_2 TOC 2000 09 20 2 01 PM 14 ...

Page 22: ...1 4 INTRODUCTION User s Manual 01 Chapter 1 2000 09 20 2 30 PM 4 ...

Page 40: ...SETTING UP 2 18 User s Manual Demo pattern 02 Chapter 2 2000 09 20 2 31 PM 18 ...

Page 50: ...SETTING UP 2 28 User s Manual 02 Chapter 2 2000 09 20 2 32 PM 28 ...

Page 78: ...PAPER HANDLING User s Manual 3 28 03 Chapter 3 2000 09 20 2 33 PM 28 ...

Page 166: ...TROUBLE SHOOTING 7 12 User s Manual 07 Chapter 7 2000 09 20 2 40 PM 12 ...

Page 170: ...8 4 User s Manual INSTALLING OPTIONS 08 Chapter 8 2000 09 20 2 41 PM 4 ...

Page 172: ...SUPPLIES AND OPTIONS A 2 User s Manual A Appendix A 2000 09 20 2 51 PM 2 ...

Page 182: ...PRINTER AND PAPER SPECIFICATIONS B 10 User s Manual B Appendix B 2000 09 20 2 51 PM 10 ...

Page 252: ...GL 8 User s Manual GLOSSARY OF TERMS G Glossary 2000 09 20 2 47 PM 8 ...

Page 260: ...IN 8 User s Manual INDEX H Index 2000 09 20 2 46 PM 8 ...

Page 262: ...C147 E042 05EN ...