En-12

7. FIELD SETTING

There are 3 methods for address setting by FIELD SETTING as follows.

Set by either of the methods.

Each setting method is described (1) to (3) below.

(1) IU AD, REF AD SW settings: This section (7.1. Setting the address)

(2) Remote controller settings:

Refer to the wired or wireless remote controller manual

for detailed setting information. (Set IU AD, REF AD

SW to 0)

(3) Automatic address settings: Refer to the outdoor unit manual for detailed setting

information. (Set IU AD, REF AD SW to 0)

CAUTION

Be sure to turn OFF the power before performing the field setting.

Do not operate any switches other than prescribed, as it can cause the unit to operate

improperly or malfunction.

Use an insulated screwdriver to set the DIP switches.

7.1. Setting the address

Manual address setting method

The indoor unit address and the refrigerant circuit

address can also be set up through the wireless

remote controller.

IU AD

REF AD

RC AD

×10 ×1

×10 ×1

SET3

SET4

For refrigerant

circuit address

For indoor

unit address

CAUTION

Use an insulated screwdriver to set the DIP

switches.

Setting

Setting

range

Type of switch

Indoor unit address

• Rotary switch [IU AD × 1]

(Factory setting “0”)

• Rotary switch [IU AD × 10]

(Factory setting “0”)

When connecting multiple indoor units to 1

refrigerant system, set the address at IU AD SW

as shown in the Table A.

0 to 63

Setting example “2”

IU AD × 10

IU AD × 1

Refrigerant circuit address

• Rotary switch [REF AD × 1]

(Factory setting “0”)

• Rotary switch [REF AD × 10]

(Factory setting “0”)

In the case of multiple refrigerant systems, set

REF AD SW as shown in the Table A for each

refrigerant system.

Set to the same refrigerant circuit address as the

outdoor unit.

0 to 99

Setting example “63”

REF AD × 10 REF AD × 1

• If working in an environ-

ment where the wireless

remote controller can be

used, the addresses can

also be set using the

remote controller.

• If setting the addresses

using the wireless

remote controller, set

the indoor unit address

and refrigerant circuit

address to “00”.

(For information on set-

ting using the wireless

remote controller.)

* Do not set the indoor

unit address (IU AD

SW) at 64 to 99.

It may result in failure.

Table A

Address

Rotary switch

setting

Address

Rotary switch

setting

Refrigerant

circuit

REF AD SW

Indoor unit

IU AD SW

× 10

× 1

× 10

× 1

0

0

0

0

0

0

1

0

1

1

0

1

2

0

2

2

0

2

3

0

3

3

0

3

4

0

4

4

0

4

5

0

5

5

0

5

⁞

⁞

⁞

⁞

⁞

⁞

10

1

0

10

1

0

11

1

1

11

1

1

⁞

⁞

⁞

⁞

⁞

⁞

99

9

9

63

6

3

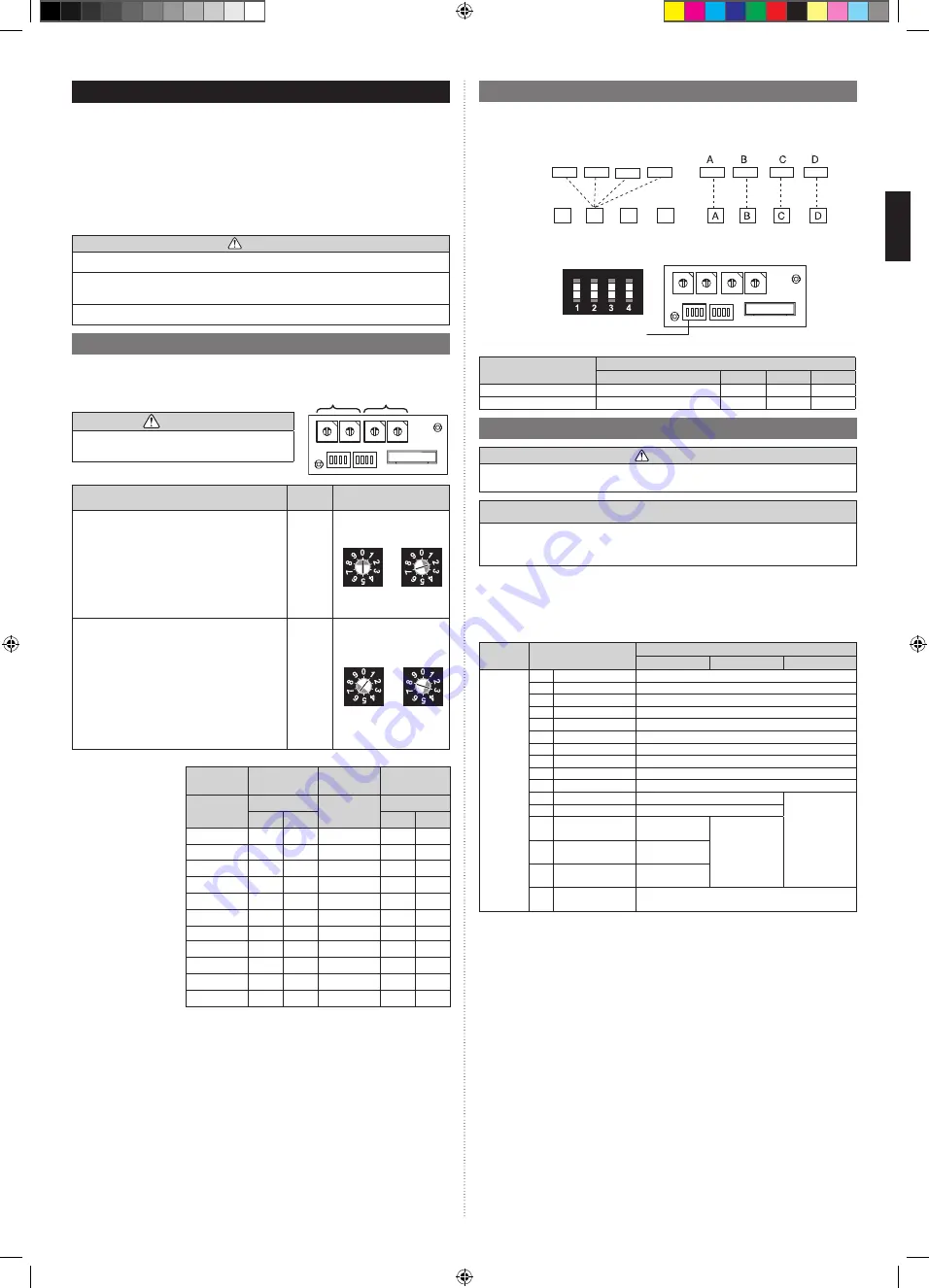

7.2. Custom code setting

Selecting the custom code prevents the indoor unit mix-up.

(Up to 4 codes can be set.)

Perform the setting for both the indoor unit and the remote controller.

Indoor

unit

Remote

controller

Confusion

Code change

Custom code setting for indoor unit

Set the DIP switch SET 3 SW1, SW2 referring to the Table B.

IU AD

REF AD

RC AD

×10 ×1

×10 ×1

SET3

SET4

SW 4

SW 3

SW 2

SW 1

Dip switch “SET 3”

ON

OFF

Table B

Custom code

A (Factory setting)

B

C

D

DIP switch SET3 SW1

OFF

ON

OFF

ON

DIP switch SET3 SW2

OFF

OFF

ON

ON

7.3. Static pressure mode

CAUTION

If the applicable static pressure does not match the static pressure mode, the static

pressure mode may be changed to another mode manually.

Recommended range of external static pressure

ARUM24: 0 and 0.56 in WG (0 and 140 Pa)

ARUM30: 0 and 0.44 in WG (0 and 110 Pa)

ARUM36: 0 and 0.36 in WG (0 and 90 Pa)

It is necessary to set up a static pressure mode for each usage of static pressure.

Static pressure can be set at site.

Relation between set values and static pressure are as the following table.

• FUNCTION SETTING can be performed with the wired or wireless remote controller.

(The remote controller is optional equipment)

• Refer to the wired or wireless remote controller manual for detailed setting information.

Function

Number

Setting Number

Setting Static Pressure

ARUM24

ARUM30

ARUM36

26

00

SP mode 00

0 in WG (0 Pa)

01

SP mode 01

0.04 in WG (10 Pa)

02

SP mode 02

0.08 in WG (20 Pa)

03

SP mode 03

0.12 in WG (30 Pa)

04

SP mode 04

0.16 in WG (40 Pa)

05

SP mode 05

0.20 in WG (50 Pa)

06

SP mode 06

0.24 in WG (60 Pa)

07

SP mode 07

0.28 in WG (70 Pa)

08

SP mode 08

0.32 in WG (80 Pa)

09

SP mode 09

0.36 in WG (90 Pa)

10

SP mode 10

0.40 in WG (100 Pa)

(0.36 in WG

(90 Pa))

11

SP mode 11

0.44 in WG (110 Pa)

12

SP mode 12

0.48 in WG

(120 Pa)

(0.44 in WG

(110 Pa))

13

SP mode 13

0.52 in WG

(130 Pa)

14

SP mode 14

0.56 in WG

(140 Pa)

31

Normal SP

(Factory setting)

0.16 in WG (40 Pa)

* Please refer to FAN PERFORMANCE CURVE within Design & Technical Data for the

features of each setting.

9373385264-02_IM_L3.indb Sec1:12

9373385264-02_IM_L3.indb Sec1:12

9/24/2019 11:06:30 AM

9/24/2019 11:06:30 AM