En-7

5. PIPE INSTALLATION-1

5.1. Opening a knock out hole

CAUTION

Be careful not to deform or scratch the panel while opening the knock out holes.

To protect the piping insulation after opening a knock out hole, remove any burrs from

the edge of the hole. It is recommended to apply rust prevention paint to the edge of the

hole.

•

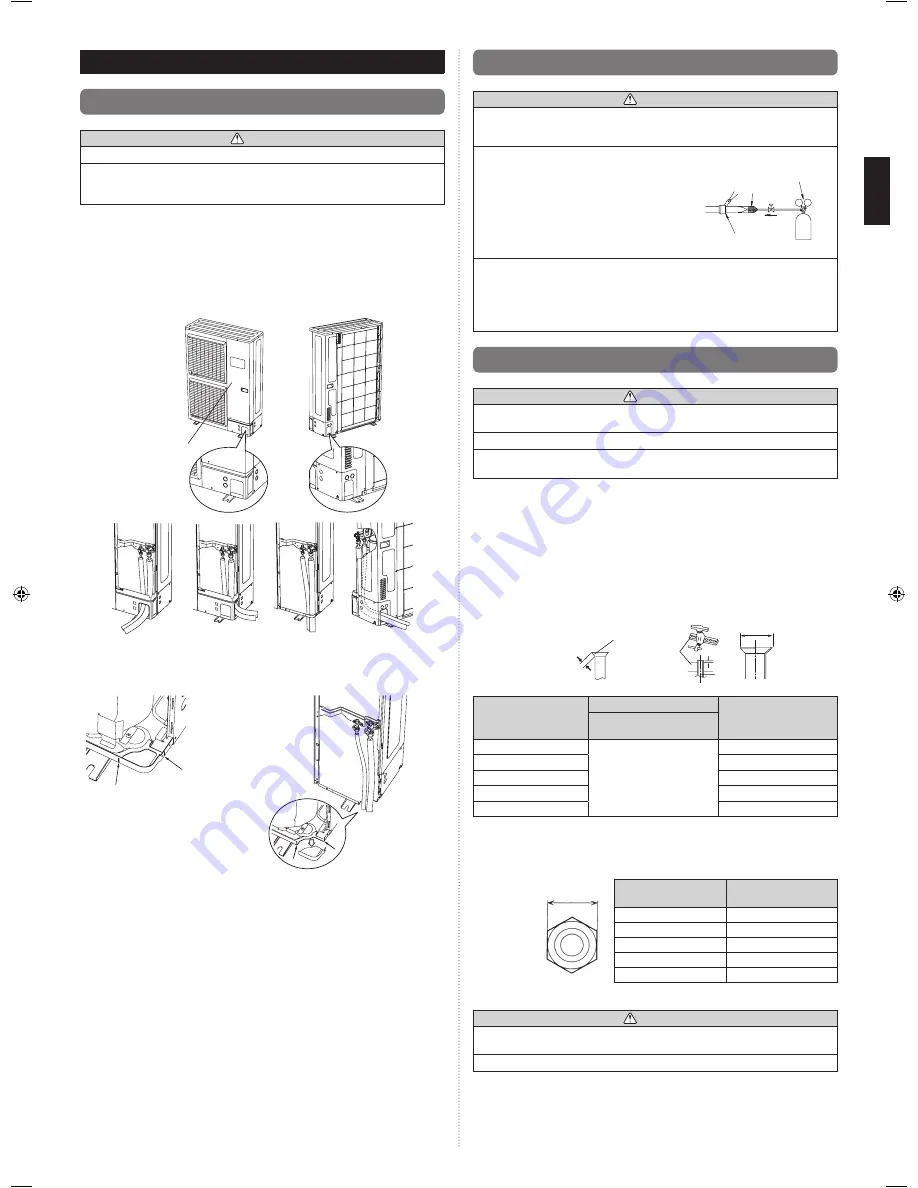

Pipes can be connected from 4 directions, front, lateral side, rear side and bottom.

(Fig. A)

•

When connecting at the bottom, remove the service panel and piping cover on the

front of the outdoor unit, and open the knock out hole provided at the bottom corner of

the piping outlet.

•

It can be installed as shown on “Fig. B” cutting out the 2 slits as indicated on “Fig. C”.

(When cutting slits, use a steel saw.)

Fig. A

Service panel

Front

connection

Bottom

connection

(No. 1)

Lateral

connection

Rear

connection

Fig. B

Fig. C

Slit

Slit

Bottom

connection

(No. 2)

5.2. Brazing

CAUTION

If air or another type of refrigerant enters the refrigeration cycle, the internal pressure in

the refrigeration cycle will become abnormally high and prevent the unit from exerting its

full performance.

Apply nitrogen gas while brazing the pipes. If a pipe is brazed without applying nitrogen

gas, an oxidation film will be created.

This can degrade performance or damage the

parts in the unit (such as the compressor or

valves).

Pressure regulating valve

Cap

Brazing area

Nitrogen gas

Nitrogen gas pressure: 0.02 MPa

(= pressure felt sufficiently on

the back of the hand)

For brazing material, use phosphor copper that does not require flux. Do not use flux to

braze pipes. If the flux is the chlorine type, it will cause the pipes to corrode.

Furthermore, if the flux contains fluoride, it will adversely affect the refrigerant pipe

system such as by degrading the refrigerant.

If fluoride is contained, quality of refrigerant deteriorates and affects the refrigerant

piping system.

5.3. Flare connection (pipe connection)

CAUTION

Do not use mineral oil on a flared part. Prevent mineral oil from getting into the system

as this would reduce the lifetime of the units.

While brazing the pipes, be sure to blow dry nitrogen gas through them.

The maximum lengths of this product are shown in the table. If the units are further apart

than this, correct operation cannot be guaranteed.

5.3.1. Flaring

Use special pipe cutter and flare tool exclusive for R410A.

(1) Cut the connection pipe to the necessary length with a pipe cutter.

(2) Hold the pipe downward so that the cuttings will not enter the pipe and remove any

burrs.

(3) Insert the flare nut (always use the flare nut attached to the indoor and outdoor

units respectively) onto the pipe and perform the flare processing with a flare tool.

Leakage of refrigerant may result if other flare nuts are used.

(4) Protect the pipes by pinching them or with tape to prevent dust, dirt, or water from

entering the pipes.

Check if [L] is flared uniformly

and is not cracked or scratched.

B

L

Pipe

A

Die

Pipe outside diameter

[in. (mm)]

Dimension A [in. (mm)]

Dimension B [in. (mm)]

Flare tool for R410A,

clutch type

1/4 (6.35)

0 to 0.020

(0 to 0.5)

3/8 (9.1)

3/8 (9.52)

1/2 (13.2)

1/2 (12.70)

5/8 (16.6)

5/8 (15.88)

3/4 (19.7)

3/4 (19.05)

15/16 (24.0)

When using conventional flare tools to flare R410A pipes, the dimension A should be

approximately 0.020 in. (0.5 mm) more than indicated in the table (for flaring with R410A

flare tools) to achieve the specified flaring. Use a thickness gauge to measure the

dimension A.

Width across

flats

Width across

flats

Pipe outside

diameter [in. (mm)]

Width across flats of

Flare nut [in. (mm)]

1/4 (6.35)

11/16 (17)

3/8 (9.52)

7/8 (22)

1/2 (12.70)

1 (26)

5/8 (15.88)

1-1/8 (29)

3/4 (19.05)

1-7/16 (36)

5.3.2. Bending pipes

CAUTION

To prevent breaking of the pipe, avoid sharp bends. Bend the pipe with a radius of

curvature of 3-15/16in. (100mm) to 5-14/16in. (150mm).

If the pipe is bent repeatedly at the same place, it will break.

•

If pipes are shaped by hand, be careful not to collapse them.

•

Do not bend the pipes at an angle of more than 90°.

• When pipes are repeatedly bent or stretched, the material will harden, making it difficult

to bend or stretch them any more.

•

Do not bend or stretch the pipes more than three times.

9379069762_IM.indb 7

3/4/2016 09:03:13