22

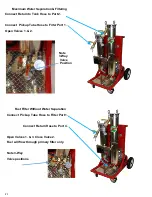

Observe Vacuum Gauge 3. two minutes after fluid appears in sight tube; The ini-

tial Vacuum reading will be determined by the elevation of the supply port 1. rel-

ative to the elevation of the fluid level in the tank being serviced. Make note of

this first gauge reading. As the bag filter accumulates debris the vacuum reading

will increase. When the gauge reading has increased

8”

Hg. above the initial

reading; the filter bag needs to be changed.

Observe the Pressure Gauge. When the gauge reads 22PSI, the coalescer filter

needs changing.

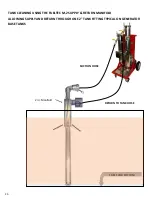

Use only Fueltec

24”

Bag Filters in this

System

1 micron

….

1M24 #241004

Use only Fueltec Filter/ Coalescers in

this System

CF

-

10 for the 950AW #241023

CF

-

20 for the 955SS #241024