Installation Tips

Trouble Shooting

Maintenance

Armature Plate must remain flexible

The armature plate must be remained movable to allow surface alignment with the magnet face. The

Magnetic Lock will lose holding force without this floating alignment.

Do not trim the rubber washers

Trimming rubber washers

will adversely affect the release of the armature plate from the magnetic lock.

Contacting surface of the Electromagnet and Armature plate must be kept free of contaminating materials.

Surfaces should be cleaned periodically with a non-abrasive cleaner. Do not spray the Electromagnet or

Armature plate surface with any lacquer chemical, this will create problems with the release of the magnetic

lock and Armature plate and might cause serious safety problems.

Problem

Possible Cause

Solution

Door will not lock

No DC voltage to lock.

Loose wire on terminal strip.

Check power supply and wiring to

magnetic lock.

Check for voltage at terminal block of

magnetic lock.

Ensure mating surfaces are clean and in

proper alignment and the armature plate

floats freely.

Check magnetic lock for low voltage or

wrong voltage setting.

Re-wire circuit switch between magnetic

lock and power source.

Remove this diode. Voltage spike

protection is on the PCB.

Check alignment of armature plate.

Reposition reed switch; contact

manufacturer for instruction.

Bad physical contact between

armature plate and face of magnet.

Circuit switch is not between

magnetic lock and power source.

Secondary diode installed across

magnetic lock.

Misalignment of armature plate.

Hall effect switch has moved inside

the magnetic block.

Reduced holding force

Delay in door release

Light panel Status is

incorrect

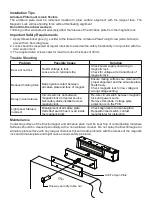

One way security dome nut

Door

Anti-Tamper-Plate

Important Safety Requirements

1. Apply thread-locker glue (i.g. Loctite) to the thread of the Armature-Plate-Fixing Screw (Allen-Screw) to

prevent from becoming loose.

2. Locks should be inspected at regular intervals to ascertain the safety functionality in conjunction with the

door environment.

3. The supplied Allen screws cater for maximum door-thickness of 45mm.

Summary of Contents for FEM3500

Page 3: ......