22. Reduce speed on slopes and sharp turns to minimize tipping or loss of control. Be

careful when changing directions on slopes. Do not start or stop suddenly on slopes.

Avoid operation on steep slopes.

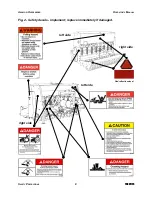

23. When using a unit, a minimum 20% of tractor and equipment weight must be on

tractor front wheels. Without this weight, tractor could tip over, causing personal

injury or death. The weight may be attained with a front end loader, front wheel

weights, ballast in tires or front tractor weights. When attaining a minimum 20% of

tractor and equipment weight on the front wheels, you must not exceed the ROPS

weight certification. Weigh the tractor and equipment. Do not guess or estimate!

24. Inspect the entire machine periodically

1

. Look for loose fasteners, worn or broken

parts, and leaky or loose fittings.

25. Use only the driveline supplied with the implement. Do not use it if it is missing any

shield or safety protection.

26. Pass diagonally through sharp dips and avoid sharp drops to prevent “hanging up”

tractor and implement.

27. Avoid sudden starts and stops while traveling up or downhill.

28. Always use down slopes; never across the face. Avoid operation on steep slopes.

Slow down on sharp turns and slopes to prevent tipping and or loss of control.

3.02 - Set Up

Notice to dealer:

Pre-delivery setup and service including lubrication is the

responsibility of the authorized dealer. It is up to him to assure that the machine is in

perfect condition and ready to be used. It is his responsibility to ensure that the

customer is aware of all safety aspects and operational procedures for the implement.

He must also fill out the Pre-Delivery Checklist

2

prior to delivering the implement.

CAUTION: Stand clear of bands when cutting as they could be under sufficient

tension to cause them to fly loose. Take care in removing bands and wire. They

often have extremely sharp edges and cut very easily.

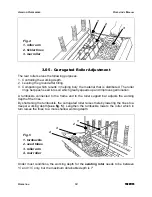

Although the machine usually arrives set up, ready to use, it is important to check

certain aspects of the machine before using it. Adjustments are normally necessary in

order to adapt the aerator-overseeder to work under a given condition.

Check the oil in the gearbox. The proper level should be between

1

/

2

and

2

/

3

full. Use 90

wt. or 140 wt. gear oil. Make sure the breather cap is clear and tight in the gearbox.

Check all hardware for tightness, especially the bolts holding the 3 point hitch

3

.

Grease the cross and bearings and the telescopic tubes of the driveline.

Ensure that the drive chains are well greased, both the tiller drive chain in the chain

housing on the left side

(see fig. 16)

as well as the roller chain which drives the hopper

O

PERATION

12

FRONTIER

A

ERATOR

-O

VERSEEDER

O

PERATOR

’

S

M

ANUAL

3

See Table 4, page 29.

2

See Chapter 7 - Pre-Delivery Checklist.

1

See Chapter 4 - Maintenance.