070.655-IOM (FEB 22)

Page 22

SBTP Rotary Screw Compressor

Maintenance

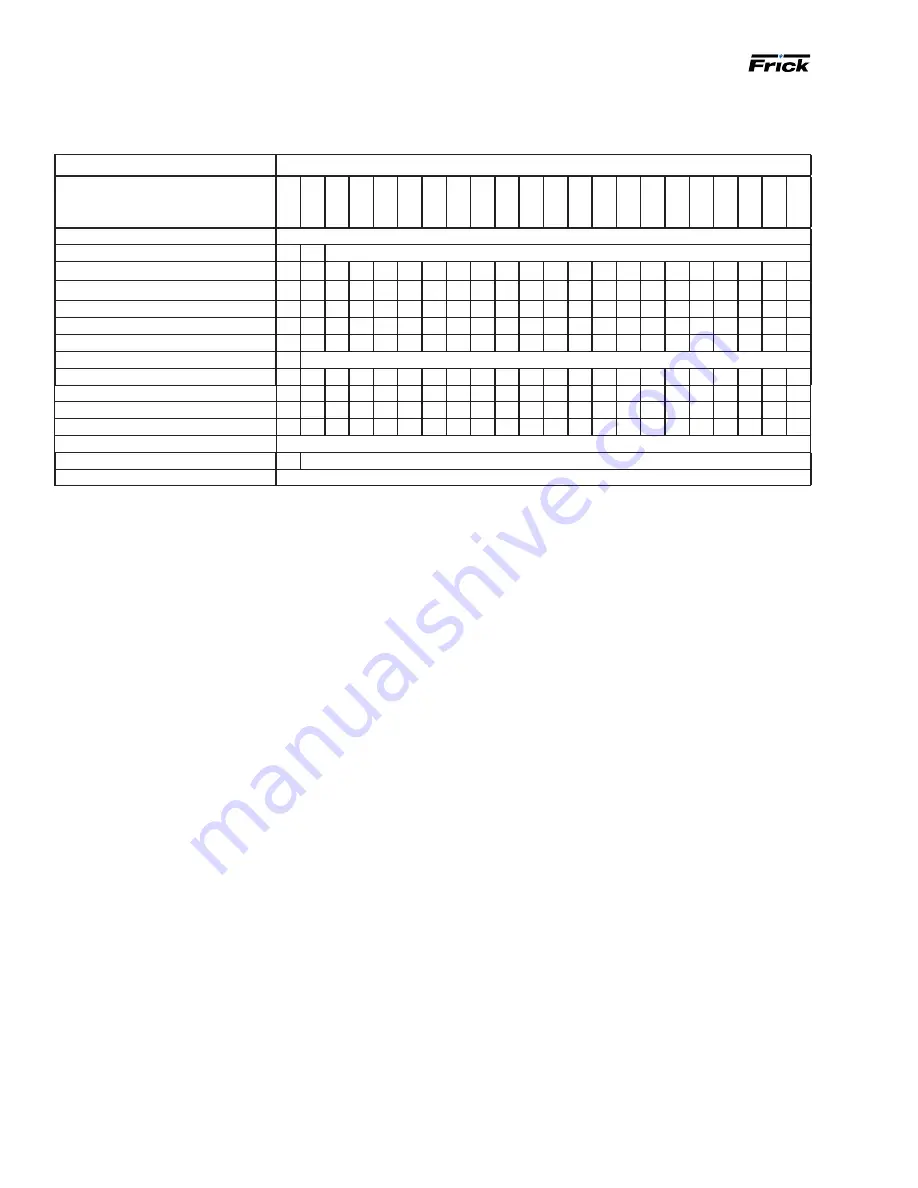

Maintenance schedule

Follow this schedule to ensure trouble-free operation of the compressor unit.

Frequency or hours of operation, maximum

Maintenance

200

1000

5000

8000

10

,000

15

,000

20

,000

25

,000

30

,000

35

,000

40

,000

45

,000

50

,000

55

,000

60

,000

65

,000

70

,000

75

,000

80

,000

85

,000

90

,000

95

,000

Change oil

As directed by oil analysis

Oil analysis

Every 6 months

Replace oil filters

Clean oil strainers

Clean liquid strainers

Replace coalescers

Check and clean suction strainer

Check coupling

Annually regardless of operating hours

Check alignment

Suction and discharge flange bolts

Check electrical connections

Check sensor calibration

Test high pressure cut-out

Test annually

Vibration analysis

Every 6 months, more frequently if levels increase

Replace shaft seal

When leak rate exceeds 20 drops per min

Vibration analysis

Periodic vibration analysis can be useful in detecting bear-

ing wear and other mechanical failures. If you are using

vibration analysis as part of your preventive maintenance

program, take the following guidelines into consideration:

• Always take vibration readings from exactly the same

places and at exactly the same percentage of load.

• Use vibration readings taken from the new unit at

start-up as the baseline reference.

• Evaluate vibration readings carefully because the in-

strument range and function used can vary, which can

easily lead to misinterpreting findings.

• Other equipment operating in the vicinity or connected

to the same piping as the unit can influence vibration

readings.

• If using proximity probes, collect data and evaluate

periodically in the same manner as vibration readings.

Oil quality and analysis

High quality and suitable oil is necessary to ensure com-

pressor longevity and reliability. Oil quality rapidly dete-

riorates in systems containing moisture and air or other

contaminants. In order to ensure the quality of the oil in

the compressor unit, adhere to the following points:

• Only use Frick oil or high quality oils approved by John-

son Controls-Frick for your application.

•

Only use Frick filter elements. Substitutions must be

approved in writing by Johnson Controls-Frick engi-

neering or warranty claim may be denied.

• Participate in a regular, periodic oil analysis program to

maintain oil and system integrity.

Operating log

Using an

permits thorough analysis

of the operation of a system by those responsible for its

maintenance and servicing. Continual recording of gauge

pressures, temperatures, and other pertinent information

enables the observer and serviceman to be constantly

familiar with the operation of the system and to recognize

immediately any deviations from normal operating condi-

tions. Frick suggests to take readings at least daily.

Notes:

• When checking the coupling, check bolts, shim packs, center inserts, keys, and all bolt torques.

•

For suction and discharge flange bolts, verify the tightness of the bolts.

•

For electrical connections, check and torque all terminals in the processor and starter panel as shown in the specification posted in the

enclosure.

• For senor calibration, check the calibration of the slide valve, slide stop, pressures and temperatures. Conduct calibration with

NIST- certified devices.

• For vibration analysis, baseline vibration analysis is required during initial commissioning. Vibration measurement must be carried out con-

tinuously to obtain optimum preventive control on bearings.

•

When replacing oil filters, the filter may need to be changed more frequently based on differential pressure or as directed by oil analysis.

• When checking alignment, refer to

070.210-IB, Screw Compressor Foundations

for foot-mounting alignment.