REV03MAR99NB PRO3.P65

Page 3

INSTALLATION

Before proceeding with any installation, please check to make sure you have the

following components.

STOP

and call the factory if any components are missing.

Components supplied are as follows :

1)

PRO GOVERNOR

controller

2) Extension cable for power

3) Throttle servomotor

4) Extension cable for servomotor

5) Extension cable for High Idle

6) Pressure transducer& Extension cable for pressure transducer

7) Alternator cable

Installation for

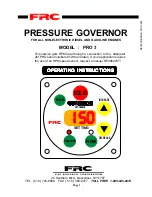

PRO 3

is extremely simple. The control module can be mounted any-

where on the pump panel.

PRO 3

control module has a square flange with an overall

dimensions of 4.25" X 4.25" . A cutout hole of 3.75" in diameter is required. To ensure

proper installation, follow the following procedures carefully:

1)

CONTROL MODULE

: Locate a suitable position on the pump panel and make sure

that check engine and stop engine indicators are closely mounted near

PRO 3

controller.

a)

Locate the center of the cutout hole and make a 3.75" diameter cutout.

b)

Insert the

PRO 3

controller into the cutout hole and locate the four 10-32 mount-

ing screw holes on the four corners of the flange.

c)

The dimensions for locating the cutout hole and the mounting screw holes can be

found in Figure 9.

2)

THROTTLE SERVO-MOTOR

Mark the point at which the servo-motor arm exits

the housing at idle and then when the engine is at max. The distance between these

points is the total motion of the actuator rod. The total motion of the actuator rod is

approximately 1 7/8" inches. The motion of the throttle arm at the slip fitting must be

slightly more than 1 7/8" to prevent breakage of the arm. If it is not, you have 2 choices:

i)

You may allow a little more clearance between the stop nuts and the slip fitting (1/

8" minimum is necessary to ensure correct engine idle). Doing that, however, may

delay the initial engine response somewhat.

Summary of Contents for GOVERNOR PRO 3

Page 19: ...servo p65 REV15AUG97 Page 19...