Commissioning the Camera using CamSet

.

The best way to test the operation of the camera is to use the programme called

CamSet

which is run from a PC.

This programme runs on any PC with a Windows operating system. To ensure correct

operation the following files should be loaded off the main C: directory into the directory e.g.

C:/WinCam:

Camset50.exe

MSCOMM32.OCX

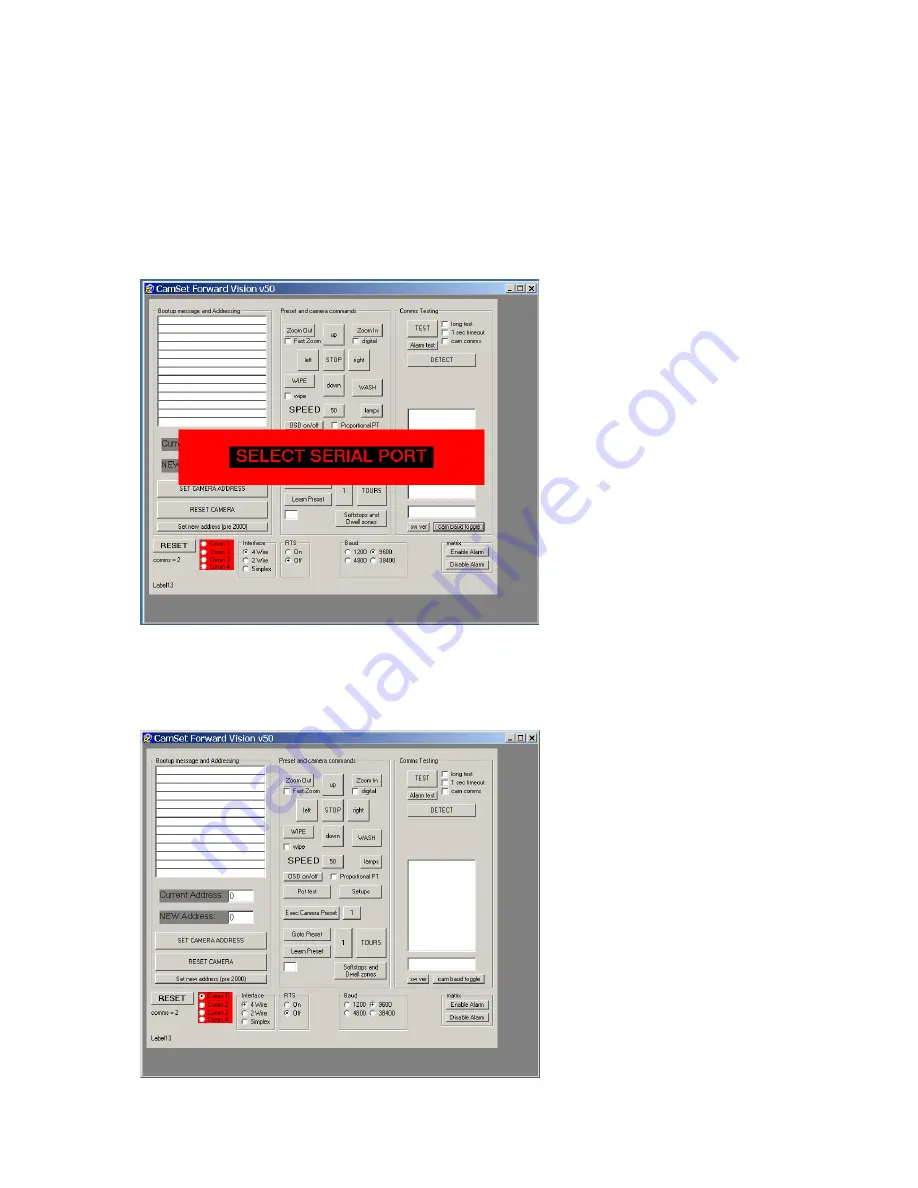

When opened the CamSet screen

will show as follows:

Firstly to get rid of the red

banner, the Serial port must be

selected. For a notebook this can

only generally be “

Comm 1

”.

This should be selected with the

mouse. Alternatively for

notebooks without a serial

Comm port, a USB to RS232

adaptor can be used in which

case the Comm port selected

must be that mapped by

windows for the USB to RS232

port (usually Comm3 or

Comm4).

Once selected the programme is

ready to receive messages from

the camera.

A camera power on reset should put a start up message in the thirteen text box windows in

the top left of the programme panel (Boot up message and addressing). The address of the

camera detected during boot up will be automatically loaded into the Current Address: box

At switch on, the camera goes

through an initialisation routine.

Whilst doing so, it sends out

ASCII readable messages on the

RS422 / RS485 telemetry link. It

also displays on Video a start up

text message for 1-2 seconds

identifying the camera address

and software version No. loaded

into the camera.

The text on screen message

appear in red and looks similar

to:

CAM 1 SW 22AUG120GW

Where “

CAM 1

” is the current

address of the camera.

MIC1-440 Instruction Manual Page 11 of 43 Issue 2