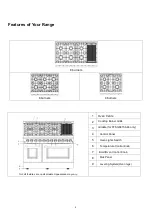

Opening width

W

30" Model

30" (762mm)

36" Model

36" (914mm)

48" Model

48" (1219mm)

Exhaust Hood Installation

The bottom of the hood should be 30" min. to 36" above the

countertop. This would typically result in the bottom of the hood

being 66" to 72" above the floor. These dimensions provide

safe and efficient operation of the hood.

After Installation:

1. Check ignition of cooktop burners.

2. Check the air shutter adjustment – sharp blue flame, with no

yellow tipping or lifting flames.

3. Check ignition of oven burner.

4. Visually check tubular burner (oven burner) re-ignition to be

sure both rows of burner ports are relighting each time.

5. Check for gas leaks at all gas connections (using a gas

detector, never a flame).

6. Check oven bake and convection bake function.

Gas Conversion Operation

This cooking range can be used with LP gas and NG gas. It is shipped from the factory adjusted for use with

NG(Nature Gas). Injector for LP gas are included. Follow the instruction shown below for gas conversion.

WARNING

Gas conversion shall be conducted by a factory- trained professional. Call

the customer service hotline to identify a factory-trained professional near your home.

Minimum to cabinets on either sides of the range

W

Opening width

Min.

To wall either side

Maximum depth for cabinets above countertop

Front edge of

the range side

panel forward

from cabinet

To countertops

below cooktop and

at the range back

16

Summary of Contents for FFSGS6156-30

Page 1: ...FFSGS6156 30 FFSGS6156 36 FFSGS6156 48 09 03 21 dd mm yy...

Page 28: ...Wire Diagram 28...

Page 29: ...29...

Page 30: ...30...