Service

Latch adjustment

To adjust for proper latch engagement

1. Loosen striker plate mounting screws (Fig. 8.1).

2. Move striker plate up or down as required and tighten screws.

3. Test operation of latch.

To adjust for proper gasket seal

1. Loosen striker depth adjustment screw (Fig. 9.2).

2. Adjust stop in or out and tighten screws.

3. Test operation of latch.

Door gasket replacement

1. Remove existing gasket from mounting track.

2. Verify mounting track is free of any remaining gasket material.

3. Align new gasket with mounting track and press firmly in place.

4. Open and close door, checking for proper gasket seal without

pinching against refrigerator.

5. Adjust latch and or striker as necessary for proper door closure.

Slide-out compressor tray

Follett’s slide-out compressor tray allows technicians to partially

slide the condensing unit from the refrigerator back without cutting

refrigerant lines.

1. Remove rear panel (Fig. 10.1).

2. Remove two bolts securing condensing unit to refrigerator base

(Fig. 10.2).

3. Gently slide condensing unit out (Fig. 10.3).

Note:

Do not put undue strain on the refrigerant lines.

Removing drawers

1. Pull drawer forward to stop.

2. Lift drawer front to free front rollers from sides.

3. Still lifted, pull drawer forward to free back rollers from sides.

Removing slides

1. Push slides all the way back.

2. Lift bottom of slide up and away from rollers.

8

1

2

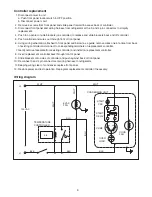

Fig. 9

20

82

64

Pro

duc

t

Mod

ule

No.

Ser

vice

No

.

Easton P

ennsylv

ania

MO

TO

R COMPRESSOR T

HER

MALL

Y PR

OTECTED

DESIGN PRESSURE HIG

H SIDE

MIN

. BRANCH CIRC

UIT AMP

AC

ITY

MAX.

BR

ANCH CIRCUIT

FUS

E SIZ

E

SINGLE

PHASE

LO

W SIDE

L

THE

U

SA

MA

DE IN

OZ

PS

IG

R

C

NS

F

UL

PA

RT NO

HZ

CHARGE

AM

PS

R

AM

PS

U

VO

LTS

CORPORA

TION

SERIAL NO

MODEL

FULL LO

AD A

MP

S

REFRIGE

RANT

1

2

3

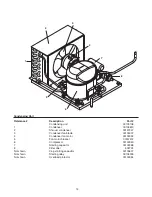

Fig. 10