F M C M 1 2 - H D O P E R A T I O N A N D M A I N T E N A N C E M A N U A L

13

•

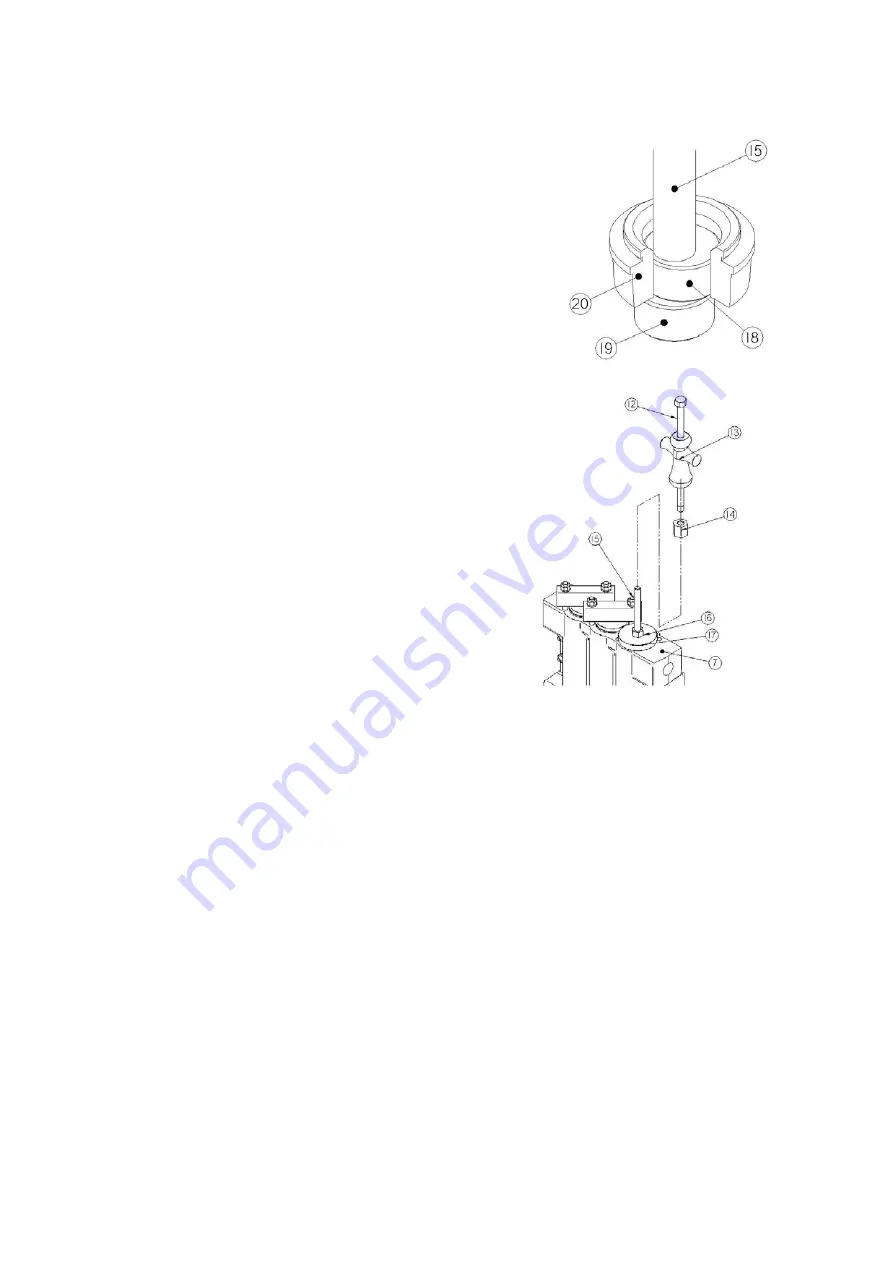

Assemble the puller guide (19) and puller eccentric (18)

on one end of the puller stem (15) as shown. There are

two guides and two eccentrics provided in the kit. Use the

slightly larger diameter ones to remove the discharge

valve seats. The smaller diameter components will be

used later when removing the suction valve seats.

•

Insert the end of the puller stem down through the discharge

valve seat (20). Work the puller guide (19) through the center

of the seat until it sits just underneath the seat. Hold the

puller stem firmly in position, then work from side to side until

the puller eccentric (18) drops down into the ID of the seat

and rests on the top of the guide as shown.

•

Hold the puller stem (15) in this position and slide

the strongback (17) down over the stem until it rests

squarely on the top of the fluid cylinder (7).

•

Run the puller nut (16) down the stem until it is hand

tight on the top of the strongback. You can now

release the puller stem, as the components will not

shift position with the nut in place.

•

Using a heavy-duty 1-5/8” wrench, tighten the puller

nut down against the strongback to apply force to

the bottom of the valve seat. Note that up to 800 ft-

lbs of torque may be required to free the valve seat

from the fluid cylinder. Do not exceed this value.

•

In many cases, torque alone will be sufficient to free

the valve seat. If unsuccessful with torque alone,

use the adapter nut (14) to connect the slide

hammer (13) and puller bolt (12) to the puller stem

(15). Leave the puller nut torqued from the previous

step. Drive the slide hammer firmly into the head of

the puller bolt to apply extra impact force to free the valve seat and lift out through the

valve cover bore in the fluid cylinder.

•

Repeat the previous steps to remove the suction valves that are located just below the

discharge valves. Replace the puller guide and eccentric with the smaller diameter parts

provided in the kit to slide through the smaller bore of the suction valve. It will be

necessary to fish out the valve spring and valve from the suction valve using a variety of

hooks and loops of string or wire since the are located too deeply in the bore of the fluid

cylinder to be removed by hand.

•

Remove the suction and discharge valves from the remaining two cylinders.

Summary of Contents for M12-HD

Page 1: ...M12 HD Piston Pump Operation Maintenance Manual ...

Page 19: ......