4-1

Chapter 4

Operation

Operating Instructions

In comparing the pressure of one system to that of another, it must first be established

that the comparator or indicating device is adjusted correctly. The adjustment must assure

the operator that all hydraulic and pneumatic heads have been accounted.

With the transducer connected between two systems and prepared for operation, the

power is turned on and the circuit allowed to warm up for ten minutes. A sequence of

operations must be adopted in which one of the systems is always at a higher pressure

than the other during the period of change from one pressure to another. If there is a

choice, it is of some advantage, in a liquid-to-gas system, to maintain the higher pressure

in the liquid system during the period of change. This procedure is not difficult to execute

for both increasing and decreasing changes in pressures. If it is intended to raise both

system pressures from one level to a higher one, the liquid pressure is raised first to a

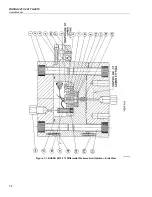

value somewhat below the final one. The diaphragm of the differential pressure cell is

driven to the lower cavity surface where it supports the excess liquid pressure. The

operator is then free to concentrate on raising the gas pressure to, but not in excess of, the

liquid pressure. As the final pressure is approached, it is usually possible to raise both

systems simultaneously, while keeping them sufficiently balanced for the meter pointer to

remain on scale.

Before starting a measurement on a liquid-to-gas system, the differential pressure

transducer is intentionally over-ranged in the direction proposed by the adopted

procedure; i.e.; from the liquid side. The pressure is allowed to remain for a minute or so

and then released. In some manner, the liquid system must be opened to atmosphere at a

point level with the diaphragm. An open-tube manometer valve opened and the gas

system also opened to atmosphere, the liquid is adjusted to stand in the tube at the height

of the diaphragm. Under these conditions, the pressure across the diaphragm is zero. The

electrical circuit, with sensitivity set at maximum or whatever value has been chosen,

may then be adjusted for the meter to indicate zero

Δ

P. As the manometer valve is closed,

the pumping action of the stem causes the liquid to rise slightly in the tube and the meter

pointer to deflect. The deflection is a normal one which results from the disturbance of

the liquid in the tube.

Before the measurement is begun, the sensitivity is reduced by placing the shunt switch

in the ON position. The shunt switch reduces the gain of the circuit by a factor of

approximately 1000. First the liquid pressure and then the gas pressure is raised in the

manner described above. As the gas pressure becomes approximately equal to that of the

liquid, it will be observed that the two pressures will rise simultaneously as the increase

in gas pressure is continued. At this time, the diaphragm is being forced away from the

lower cavity surface by the gas. The displacement of the diaphragm increases the

pressure in the liquid system. Although the two pressures are approximately equal, a