HWMA2 USER INSTRUCTIONS ENGLISH - 06/16

Page 13 of 39

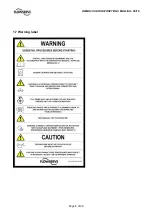

This also includes the liquids and or gases in the

"seal system" or other utilities.

Make sure that hazardous substances are

disposed of safety and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the current

regulations at all times.

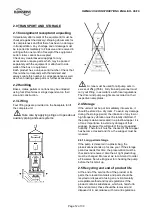

3.0 DESCRIPTION

3.1 Configuration

The model HWMA2 belongs to Flowserves family of

API 610 vertical inline pumps.

The hydraulics are designed for operating flexibility

and consist of:

•

a semi open radial vaned impeller to guarantee

optimum performance

•

a circular volute with a single caned diffuser to

minimize hydraulic forces

The pump unit is available in two stage opposed

impeller configuration. For low NPSHA applications

an inducer is available.

The sense of rotation of the pump is

clockwise (CW), looking from the coupling to the shaft

end of the pump.

3.2 Nomenclature

Example:

2x3x12HWMA2 - Ind.

2

Discharge flange in inch

3

Suction flange in inch

12

max. impeller size in inch

2

2 stage

Ind

indicates Inducer as option

3.3 Design of major parts

3.3.1 Pump casing

Vertical inline design with flanged suction elbow and

integrated baseplate. It is directly flanged to the motor

stand, which itself is flanged to the motor. Back pull

out design for easy maintenance, so the casing

remains on its foundation in case of repair.

3.3.2 Hydraulics

A circular volute in combination with a single caned

diffuser is inserted into the pump casing. A radial

vaned semi open impeller is used to ensure optimal

performance.

3.4 Performance and operating limits

In the interest of operator safety

the unit must not be operated above the nameplate

conditions. Such operation could result in unit failure

causing injury to operating personnel. Consult

instruction book for correct operation and

maintenance of the pump and its supporting

components.

4.0 INSTALLATION

Equipment operated in hazardous locations

must comply with the relevant explosion protection

regulations, see section 1.6.4,

Products used in

potentially explosive atmospheres.

4.1 Location

The pump should be located to allow room for

access, ventilation, maintenance and inspection with

ample headroom for lifting and should be as close as

practicable to the supply of liquid to be pumped.

Refer to the general arrangement drawing for the

pump set.

4.2 Part Assemblies

The pumps are delivered completely mounted and

prealigned with the motor. Also the shaft seal is in the

correct position. Final alignment after complete

installation is necessary. If drivers and/or seal systems

are delivered separately, follow the assembly

procedure in section 6.8.

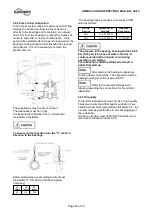

4.3 Foundation

The foundation shall be located on a place that allows

a minimum of pipe work and that is easily accessible

for inspection during operation. According to the

environment the foundation may consist of concrete

or of steel. It must be rigid and heavy enough to

absorb normal vibrations and shocks.

4.3.1 Horizontal alignment of the baseplate

Horizontal alignment is done with levelling screws.

Use a spirit level for correct horizontal alignment of

the baseplate.

The max. misalignment is 0.5 mm/m

baseplate length.