HDX USER INSTRUCTIONS ENGLISH 85392696 - 01/11

Page 43 of 60

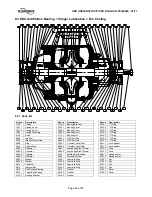

i) Lift and install lower halves of thrust and line

bearing housings against their respective seats

on casing brackets. Tighten all bolting.

j) Pour a small amount of lubricating oil on lower

halves of sleeve bearing linings. Raise shaft a

slight amount and roll in lower halves of sleeve

bearings. Position oil rings correctly.

k) Pour a small amount of oil on shaft journal

bearings and install upper halves of sleeve

bearings. Install and tighten calibrated screws.

l) Check that rotor turns freely by hand.

m) Apply a liquid gasket to bearing body joint faces

and install upper halves of thrust and line bearing

housings. Secure with bolting and dowels. Take

care to position correctly in their respective seats,

all oil seals and labyrinth rings.

n) Set oil shields on shaft by pushing them against

labyrinths and withdrawing them about 3 mm.

Secure with set screws.

o) Fit “O” ring in place, install thrust bearing outer

cover and tighten bolting.

p) Install fan guard and fan, if any.

q) Check rotor end float. This should be 0.05 to 0.15

mm.

r) Install nuts securing mechanical seal plate

assembly to stuffing box at both ends of pump.

Tighten nuts evenly.

s) Finally set seal assemblies according the

manufacturer’s instructions.

t) Turn rotor by hand to ensure there are no rubs or

binding.

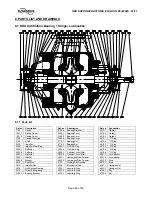

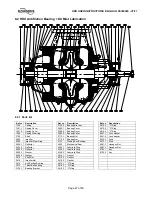

6.9.3.3 KTB

a) Install all oil shields together with respective

labyrinth rings from each end of shaft, in their

respective position. Fit “O” rings in labyrinth rings.

Do not tighten oil shield set screws.

b) Lift and install lower halves of thrust and line

bearing housings against their respective seats

on stuffing box brackets. Tighten all bolting.

c) Pour a small amount of lubricating oil on lower

halves of sleeve bearing linings. Raise shaft a

slight amount and roll in lower halves of sleeve

bearings.

d) Pour a small amount of oil on shaft journal

bearings and install upper halves of sleeve

bearings.

e) Install thrust bearing inboard seal in two halves.

f) Install inboard shim.

g) Install thrust collar key and thrust collar.

h) Install locknut and pull up tight against thrust

collar, then fit securing screws to lock nut.

i) Install thrust bearings parts (split base rings,

leveling plates and shoes) according Kingsbury’s

instructions.

j) Check that rotor is axially centralized, and

establish total thrust end play, (about 0.28 mm)

by using shim or machining at inner face of thrust

bearing cover. See Fig. 6.5

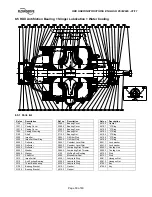

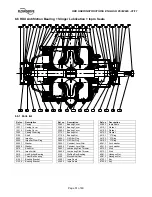

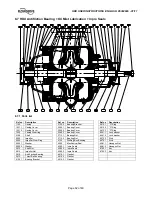

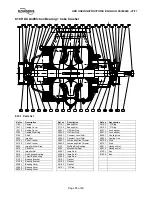

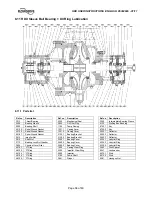

Figure 6.6

k) Apply a liquid gasket to bearing body joint faces

and install upper halves of thrust and line bearing

housings. Secure with bolting and dowels. Take

care to position correctly in their respective seats,

oil seals and labyrinth rings.

l) Set oil shields on shaft by pushing them against

labyrinths and withdrawing them about 3 mm.

Secure with set screws.

m) Fit “O” ring in place, install thrust bearing outer

cover and tighten bolting.

n) Install nuts securing mechanical seal plate

assembly to stuffing box at both ends of pump.

Tighten nuts evenly.

o) Finally set seal assemblies according the

manufacturer’s instructions.

p) Turn rotor by hand to ensure there are no rubs or

binding.

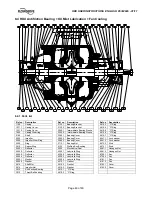

6.9.4 Final assembly

a) Install coupling key and pump half coupling,

coupling nut and coupling nut set screws.

b) Check coupling/shaft alignment as described

under Section 4.5 and assemble coupling.

c) Install coupling guard.

d) Replace all auxiliary piping, instrumentation and

pipe plugs.

e) Install oilers and fill bearing housings to correct

oil level.

f) Refer to Section 5.

SHIMS