INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE:

F84L Series Liquid Relief Valve

Rev. J

Page 12 of 18

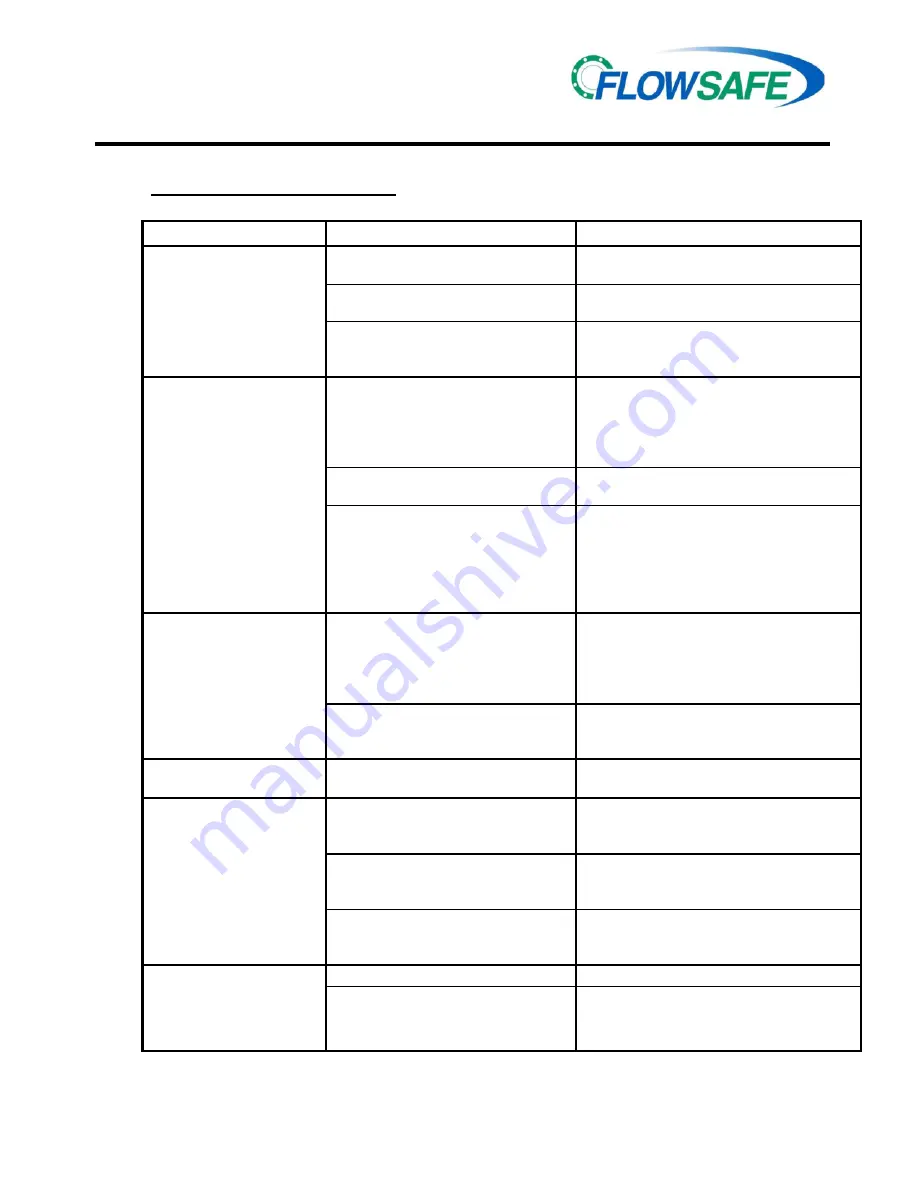

6.0

TROUBLESHOOTING GUIDE:

Symptom

Possible Cause

Remedy

The valve leaks around

the bushing.

Inadequate bushing torque.

Tighten until the bushing bottoms firmly

on the body.

Sealing surface on body or

bushing is damaged.

Inspect and polish sealing surfaces.

Bushing seal is damaged or

contaminated.

Remove bushing seal. If damaged,

replace with new seal. If contaminated,

clean and replace.

The valve leaks through

the outlet.

Seat or nozzle seating surface is

damaged or contaminated.

Disassemble the valve, remove the

spindle, and examine the seat and

seating surface under magnification. If

damaged, replace with new seat; if

contaminated, clean and reinstall.

Uneven torque on body-to-bonnet

bolts.

Torque bolts evenly (see Section 3.2 for

values)

Operating pressure is too close to

set pressure.

Operating pressure should be less than

90% of set pressure for F84L’s at most

pressures, but less than 80-85% of

set pressures ≤ 500 psig for the F84L-2

(HP), 300 psig for the F84L-2 (LP), or

100 psig for bolted-bonnet sizes.

The valve leaks through

the atmospheric vent

hole in bonnet.

Worn / damaged spindle or seals.

Disassemble valve, remove spindle

assembly, and inspect spindle and two

seals on upper neck. Look for nicks,

tears, or flat spots. Replace as

necessary.

Pipe plugs are not installed

properly.

Tighten or reinstall plug(s).

The valve does not

close.

The spindle is stuck.

Disassemble and check for binding.

Deburr or replace parts.

The valve opens below

the designated set point.

The spring preload is low due to

misadjustment, vibration, or other.

Adjust pressure adjusting screw in

(clockwise). Ensure PA screw lock nut

and cap are tight.

The seat leaks due to possible

damage, allowing early simmer

and pop.

Disassemble and inspect seat; replace

if damaged.

Spring washer is not in proper

contact with spindle.

Ensure that dimpled area of spring

washer is aligned with top of spindle.

The valve opens above

the designated set point.

The spring preload is high.

Adjust PA screw out (counterclockwise).

The spindle is stuck or sticking.

Disassemble and check for binding.

Deburr or replace parts.