GB

GB

21

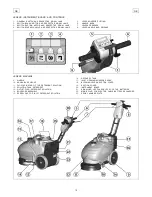

FRONT SQUEEGEE RUBBER REPLACEMENT

Check the wear of the squeegee rubber and

eventually replace it.

For the replacement it is necessary to:

1. Lower the squeegee rotating to the lower

part the handle lever (5) placed in the

centre of the handle bar.

2. Tip over the machine backwards (see

under “POSITIONING OF THE MACHINE FOR

MAINTENANCE AND PARKING") paying

attention to remember to switch off the general

switch and to empty the tanks before tipping

over the machine.

3. With the machine in this position proceed

to disassemble the squeegee and then the rear

squeegee

rubber

(see

under

“REAR

SQUEEGEE RUBBER REPLACEMENT”).

4. Take off the wing nuts (6) placed in the

upper part of the squeegee body separating

then the two metal parts that form it to take

off the front rubber.

5. Clean with a water jet all the components.

To reassemble the squeegee repeat reverse

the operations above-mentioned.

TROUBLESHOOTING GUIDE

THE SUCTION MOTOR DOES NOT WORK

1. Check the charge level of the batteries that

is visible activating first the geneal switch (1)

(see under “BATTERIES RECHARGING”).

2. Verify that the suction motor switch (3) is

activated checking that its signal lamp is on.

3. Check the level in the recovery tank (see

under

“OVERFLOW

DEVICE”)

and

if

necessary, empty the tank.

If the problem persists, please contact the

authorized technical assistance.

THE BRUSH MOTOR DOES NOT WORK

1. Check the charge level of the batteries that

is visible activating first the geneal switch (1)

(see under “BATTERIES RECHARGING”).

2. Verify that the bursh motor switch (2) is

activated checking that its signal lamp is on.

3. Activate the levers presence (5).

4. Check that the safety device of the brush

lifting or the brush wear did not intervene.

If the problem persists, please contact the

authorized technical assistance.

INSUFFICIENT WATER ON THE BRUSH

1. Check that the solenoid valve switch (8)

is activated verifying that the singal lamp is on.

2. Check the level of the liquid in the solution

tank (see under “DETERGENT SOLUTION

TANK”).

3. Check that the adjuster of the detergent

solution flow (11) placed in front underneath

the solution tank is sufficiently open.

4. Activate the levers presence (5).

If the problem persists, please contact the

authorized technical assistance.

THE MACHINE DOES NOT CLEAN PROPERLY

1. The brush does not have the suitable bristle

dimension: use only original brushes. For

advice, contact the authorized technical

assistance.

2. The detergent solution is insufficient: open

more the adjuster of the detergent solution flow

(11).

3. Check that the liquid detergent is in the

recommended percentage.

Contact the authorized technical assistance for

advice.

THE SQUEEGEE DOES NOT DRY

PERFECTLY

1. Check that the squeegee rubbers are clean.

2. Check that the coupling of the suction hose

is correctly inserted in the proper seat on the

recovery tank.

3. Intervene on the suction filter cleaning it.

4. Replace the rubbers if worn.

5. Check that the suction motor switch is on.

6. Check the level in the recovery tank (see

under

“OVERFLOW

DEVICE”)

and

if

necessary, empty the tank.

EXCESSIVE FOAM PRODUCTION

Check that low foam detergent has been used.

Eventually add small quantities of anti foam

liquid into the recovery tank.

Please be aware that a bigger quantity of

foam is produced when the floor is not very

dirty. In this case please dilute detergent

solution.