GB

GB

17

BEFORE USE

HANDLING OF THE PACKED MACHINE

The machine is supplied with suitable packing.

The total weight is 75 kg.

Packing dimensions:

Base: 78 cm x 40 cm

Height: 62 cm

ATTENTION:

Do not place more than 2 packings on top.

UNPACKING OF THE MACHINE

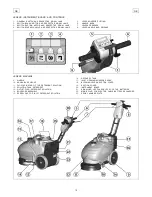

1. Open the packing as shown in the figure.

2. Take off the machine from the packing

avoiding heavy contacts to mechanical parts.

3. Keep the packing for eventual transport

needs.

MOVEMENTS OF THE HANDLE BAR

The handle bar in the package arrives in

closed position.

To rotate the handle bar in one of the

different

working

positions enabling

the

movement of the machine:

1. Act upon the release lever (8) present

near the handle bars.

2. Rotate the handle bar into the working

position maintaining the release lever (8)

pressed.

3. Let go the release lever (8) to obtain the

blocakge of the handle bar.

Act in the same way for further height

adjustment of the handle bar in order to find

the most comfortable working position.

BATTERIES

This machine is supplied with two batteries

already connected in series, placed in its

appropriate compartment under the recovery

tank.

In case the batteries need to be disassembled

and/or replaced, please contact the authorized

technical assistance.

In fact, the replacement must be made

exclusively with batteries which have the

identical performances as the ones already

installed.

To reach the battery compartment it is

necessary to:

1. Take off the squeegee hose from its seat

(17).

2. Take off the suction filter cover (19) after

turning the blocking levers (18).

3. Lift and take off the recovery tank (16)

holding it from the provided handles obtained

one behind and the other in front of the tank.

ATTENTION:

Strictly follow manufacturer/distributor indications

for the maintenance and daily recharge of the

batteries. All installation and maintenance

operations must be executed by specialized

staff, using suitable protection accessories.

BATTERIES RECHARGING

(STANDARD VERSION WITH AGM

BATTERIES)

The charge level of the batteries is visible

activating first the general switch (1) placed

on the instrument board, through three

luminous leds placed on the frame in the rear

part of the machine.

A: green led on = batteries charged.

B: orange led on = level at half charge.

C: red led on = complete discharge of the

batteries with consequent automatic switching

off of all the machine's function.

In order not to cause permanent damages to

the batteries, it is essential to arrive to their

complete discharge every 6/7 cycles, providing

for the recharge only when the red signal of

discharged batteries is activated.

In fact, an extended series of charging cycles

carried out when the batteries still have a

residual charge, causes a battery deterioration

and a consequent charge and the battery itself.

NOTE: Never leave batteries completely

discharged even if the machine is not used.

During the recharging operations a device is

activated that forbids the machine's functioning.

Bring the machine on a levelled surface near

to a single-phase socket type CEE 7/7, with

tension 230V, frequency 50Hz, nominal current

10A.

Switch off the general switch (1).

Connect the mains cable supplied with the

machine both to the machine and to the mains

socket as indicated in the figure.

At the end of the recharging phase take off

the mains cable.

BATTERIES RECHARGING

(PLUS VERSION WITH XFC BATTERIES)

The presence of a label with the writing

“plus”, placed on the frame in the rear part

of the machine, identifies the version equipped

with pure lead batteries (XFC) and its

suitable battery recharger.

The charge level of the batteries is visible

activating first the general switch (1) placed

on the instrument board, through three

luminous leds placed on the frame in the rear

part of the machine.

A: green led on = batteries charged.

B: orange led on = level at half charge.

C: red led on = complete discharge of the

batteries with consequent automatic switching

off of all the machine's function.

There is a phase in which the green led of

the general switch (1) starts to blink. This is

the best condition to carry out the battery

recharging with the possibility to continue to

work with the machine connected to the mains

system.

In fact this type of equipment contemplates a

battery recharger that supplies to the machine

a greater electric current than the required one

for the functioning of the machine. The

remaining current not used from the machine

provides for a slow recharging of the batteries.

For a faster recharging instead it is necessary

to stop working.