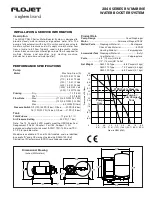

TROUBLESHOOTING CHART

CONVERSION TABLE

WARRANTY

FLOJET warrants this product to be free of defects in material

and/or workmanship for a period of one year after purchase by the

customer from FLOJET. During this one year warranty period,

FLOJET will at its option, at no charge to the customer, repair or

replace this product if found defective in material or workmanship,

with a new or reconditioned product, but not to include costs of

removal or installation.

This is only an overview of our limited warranty. If you would like a

copy of our warranty, please call or write FLOJET.

RETURN PROCEDURE

Prior to returning any product to FLOJET, call customer service for

an authorization number. This number must be written on the

outside of the shipping package. Place a note inside the

package with an explanation regarding the reason for return as

well as the authori zation number. Include your name, address and

phone number.

Symptom

Possible Cause(s)

Corrective Action

Pump will not prime or retain

• Air leak in suction line

• Repair or replace

prime after operating

• Defective check valve

• Replace

• Upper housing leaking

• Tighten bolts

• Suction lift too high

• Lower pump

• Debris in check valve(s)

• Clean check valve(s)

Pump runs but no fluid

• Faulty suction piping

• Repair or replace

• Defective check valve

• Replace

• Suction lift too high

• Lower pump

• Clogged inlet

• Clean or replace

• Inlet line valve closed

• Open valve

Motor runs too hot

• Voltage incorrect

• Check voltage

• Insufficient ventilation for motor

• Insure proper ventilation

Flow rate is low

• Piping or hose is damaged

• Clean or replace

• Clogged check valve

• Clear obstruction

• Worn check valve

• Replace

• Voltage incorrect

• Check voltage

• Tank over pressurized

• Check tank pressure

Pump leaks

• Upper housing loose

• Tighten screws

• Pistons loose

• Tighten pistons

• Pump head loose on motor

• Tighten pump head

• Switch loose

• Tighten switch

• Defective Diaphragm

• Replace

Pump will not run

• No electricity

• Check connections, fuse, breakers

• Defective pressure switch

• Replace switch

• Motor has open circuit

• Replace

• Thermal protector has cut off

• Allow motor to cool 15-30 min

TO CONVERT

TO

MULTIPLY BY

Gallons, U.S.

Liters

3.785

Liters

Gallons, U.S.

0.264

Pounds/Sq. Inch

Bar

0.069

Bar

Pounds/Sq. Inch

14.5

Fahrenheit

Celsius

(°F-32) .556

Celsius

Fahrenheit

(°C X 1.8) + 32

Flojet is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem, Inc. 81000-290 Rev F 10/2012

www.flojet.com

U.S.A.

Flojet

17942 Cowan Avenue

Irvine, CA 92614

Phone: 949.608.3900

Fax: 949.608.3887

UNITED KINGDOM

Flojet

Bingley Road, Hoddesdon

Hertfordshire EN11 OBU

Tel:

+44 (0) 1992 450145

Fax: +44 (0) 1992 467132

JAPAN

NHK Jabsco Company Ltd.

3-21-10, Shin-Yokohama

Kohoku-Ku, Yokohama, 222

Tel:

045.475.8906

Fax: 045.475.8908

GERMANY

Jabsco GmbH

Oststrasse 28

22840 Norderstedt

Tel:

+49-40-53 53 73 -0

Fax: +49-40-53 53 73 -11

ITALY

Jabsco Marine Italia

Via Tommaseo, 6

20059 Vimercate, Milano

Tel: +39 039 685 2323

Fax: +39 039 666 307