OI. Read the installation manual

carefully before installation and

use.

11. Some models are not suitable for

drinking

water.

02. The manufacturer

will not be liable

for any personal injury, pump

damage and other property

damage due to failure to comply

with contents specified in safety

warning

signs.

12. The liquid may be high-temperature

and high-pressure; therefore, the

liquid in the system

m ust be

completely drained or the shut-off

valves on both sides must be

closed

before

moving

a nd

dismantling the pump to prevent

buming.

03. The installers and operators must

comply with local safety regulations.

04. The user must confirm that only

q ua lified

personnel

with

professionalcertification and

proficiency of this manual is

allowed to install and maintain this

product

13. If removing the exhaust bolt, high-

temperature and high-pressure

liquid will be overflew. Therefore.

it is necessary to insure that the

outflow liquid will not cause

personalinjury or damage other

para.

05. The pump must not be installed in a

place that is damp or may be

splashed

by water.

14. Ventilation must be ensured in

summer or high ambient

t e m p e rature period to avoid

condensation that may cause

electrical

malfunctions.

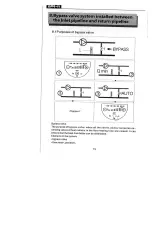

06. F=6r

convenient

access

of maintaince.

a shutoff valve

shall be installed

on

each side of the pump

15. In winter, the pump system does

not work or when the ambient

temperature drops below O "C

liquid in the system shall be

completely drained so as to avoid

frost cracking

of pump body.

07. The power supply of the pump shall

be cut off before installation and

maintainace.

08. For domestic hot water, copper or

stainless steel pump body shall be

used.

16. If the pump is left unused for a long

time, please close the pir)e valve in

the inlet and outlet of the pump and

cut off the power supply.

09. Heatsupply pipelines shall not be

frequently filled with non-softened

water so as to avoid increasing

calcium in the circulating water

inside the pipeline. which may thus

block the impeller.

17.If he flexible cord of cable ist

damaged. it must be replaced by a

qualified

person.

10. Do not start the pump without liquid.

18. Please

close the valve at the inlet of

the pump and cut off power of the

pump immediately if overheating

01

Summary of Contents for GPA-IV Series

Page 1: ......

Page 9: ...5 Electrical Connection 08...