6

5

4

3

2

1

4

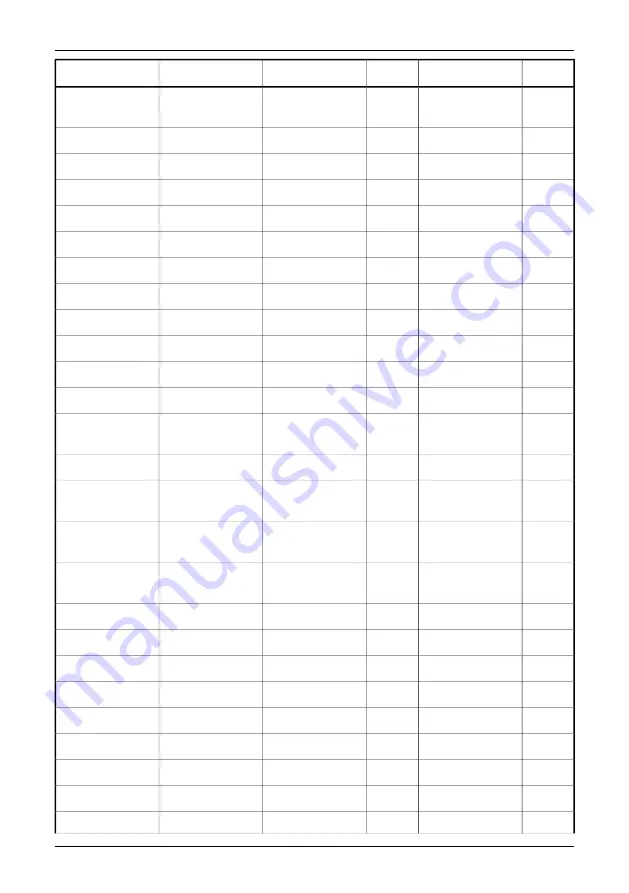

0.11

T

22

electroplated on

iron, unpolished

Nickel

2

0.37

T

200

oxidized

Nickel

4

0.37

T

227

oxidized

Nickel

4

0.85

T

1227

oxidized

Nickel

1

0.37–0.48

T

200–600

oxidized at 600°C

Nickel

4

0.045

T

122

polished

Nickel

1

0.1–0.2

T

200–1000

wire

Nickel

1

0.52–0.59

T

500–650

Nickel oxide

1

0.75–0.86

T

1000–1250

Nickel oxide

2

0.27

T

20

0.025 mm film

Oil, lubricating

2

0.46

T

20

0.050 mm film

Oil, lubricating

2

0.72

T

20

0.125 mm film

Oil, lubricating

2

0.05

T

20

film on Ni base: Ni

base only

Oil, lubricating

2

0.82

T

20

thick coating

Oil, lubricating

9

0.92–0.94

LW

70

8 different colors

and qualities

Paint

9

0.88–0.96

SW

70

8 different colors

and qualities

Paint

1

0.27–0.67

T

50–100

Aluminum, various

ages

Paint

1

0.28–0.33

T

cadmium yellow

Paint

1

0.65–0.70

T

chrome green

Paint

1

0.7–0.8

T

cobalt blue

Paint

5

0.87

SW

17

oil

Paint

6

0.94

SW

20

oil, black flat

Paint

6

0.92

SW

20

oil, black gloss

Paint

6

0.97

SW

20

oil, gray flat

Paint

6

0.96

SW

20

oil, gray gloss

Paint

1

0.92–0.96

T

100

oil, various colors

Paint

162

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

24 – Emissivity tables

Summary of Contents for Extech i5

Page 2: ......

Page 3: ...User s manual Publ No T559382 Rev a358 ENGLISH EN June 23 2009 ...

Page 6: ...vi Publ No T559382 Rev a358 ENGLISH EN June 23 2009 ...

Page 179: ......