Heat recovery unit RDKS - Technical manual

35

FläktGroup DC_9295GB_20190326_R5

We reserve the right to make changes without prior notice

EC DECLARATION OF CONFORMITY

ENCLOSURE II A

FläktGroup Sweden AB

Postal Address

Street Address

Telephone

Telefax

Reg. no:

FläktGroup Sweden AB

Fläktgatan 1

Nat 036 - 19 30 00

Nat 036 - 19 31 40

556239-2463

S-551 84

Jönköping

Int +46 36 19 30 00

Int +46 36 19 31 40

Reg. office:

Sweden

Jönköping

9850GB_RDKS_RDKG_RDAS_RDAF Declaration of conformity(2A)201901

Declaration of Conformity

In accordance with:

EU Directive for Machinery,

2006/42/EC

EU EMC Directive,

2014/30/EU

EU Directive

for Energy related Products

ErP 2009/125/EC

EU RoHS Directive,

2011/65/EU

Manufacturer

FläktGroup Sweden AB

Fläktgatan 1

551 84 Jönköping

Herewith declares that:

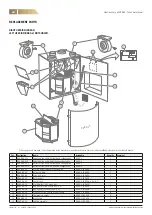

Product

Type:

Manufacturer:

Commercial name:

Ventilation unit

FläktGroup Sweden AB

MiniMASTER, RDKS

HouseMASTER, RDAS

VillaMASTER, RDAF

The machine is designed and manufactured in accordance with the following standards, in relevant parts.

EN ISO 12100

Safety of machinery – General principles for design- Risk assessment and risk reduction

EN 60204-1

Safety of machinery; electrical equipment of machines; general requirements

EN 60335-1

Household and similar electrical appliances - Safety - Part 1: General requirements

EN 60335-2-40,31

Household and similar electrical appliances - Safety - Part 2: Particular requirements

EN 61000-6-1

Electromagnetic compatibility (EMC) - Part 6-1: Generic standards - Immunity for

residential, commercial and light-industrial environments

EN 61000-6-3

Emission standard for residential, commercial and light-industrial environments

.

EN 50106

Safety of household and similar electrical appliances - Particular rules for routine tests

referring to appliances under the scope of EN 60335-1

EN 62233

Measurement methods for electromagnetic fields of household appliances and

similar

apparatus with regard to human exposure

EN 50581:2012

Technical documentation for the assessment of electrical and electronic products with

respect to the restriction of hazardous sustances

A risk analysis has been made according to requirements of the Directive for Machinery.

Authorized

To prepare technical documentation:

Ann-Sofie Andersson

Design- R&D

FläktGroup Sweden AB

Fläktgatan 1

551 84 Jönköping

The declaration applies only to the installation made according to FläkGroups instructions and assuming no

changes made to the unit.

Jönköping 2019-01-01

Björn Norling, Quality Manager, FläktGroup Sweden AB, Jönköping