Fläkt Woods

8217 GB 2014.07.02 22

Specifications are subject to alteration without notice

TopMaster Air Handling unit

CONTROL AND REGULATION EQUIPMENT

Control functions (cont.)

5. Cooling recovery

Cooling energy recovery is used when cooling load is

needed by taking advantage of any room cooling. Coo-

ling recovery is activated if the outdoor temperature is 2°

C higher than the extract air temperature and the unit is

operating in “summer mode”. If this condition is satisfied

the rotor starts and supplies 100%.

6. Night cooling

Night cooling is used in summertime to reduce cooling

load at unit start-up and to limit the maximum tempera-

ture during non-working hours. This is done by making

use of cold outside air during cool summer nights.

1. Starting conditions

a. Night cooling activated

b. Auto mode enabled

c. The unit is in the stop position as scheduled

2. Test period and evaluation

a. The unit is started at. 22.00 and then operates at

normal speed

b. At 22.15 it is determined whether night cooling is

needed or not. The following conditions must be met:

1. The unit is in “Summer mode” .

2.Outdoor temperature < Extract temperature – Delta.

3. Extract temperature > Room se Hysteresis.

c. If the above conditions are met the night cooling

starts.

3. The following take place during night cooling

a. Rotor, afterheater and any cooling are blocked.

b. The fans are switched to the high speed setting.

4. Night cooling takes place as long as the

following conditions are fulfilled:

a. Unit is in “Summer mode”.

b. Outdoor temperature < Extract temperature

–

Delta.

c. Extract temperature > Room setpoint.

d. Function’s maximum activation time is not reached.

Parameters

Value (exemple) Comment

Night cooling activated

Yes

Activated night cooling

Room setpoint

22°C

Room setpoint night cooling

Delta

5°C

Min difference room temp.

Hysteresis

2°C

Hysteresis for night cooling

Test time, start

kl. 22.00

Start time for night cooling test

Test time, off

kl.22.15

Stop time for night cooling test

Max time

540 minutes

Maximal activation time

for night cooling

6. Pressure or flow control

Pressure control (COP)

Control principle in which the unit maintains a constant

duct pressure. Normally used in variable flow systems

(VAV). Pressure sensor is supplied as a loose accessory.

Size

030 050

k-value extract air fan

56

41

k-value supply air fan

55

49

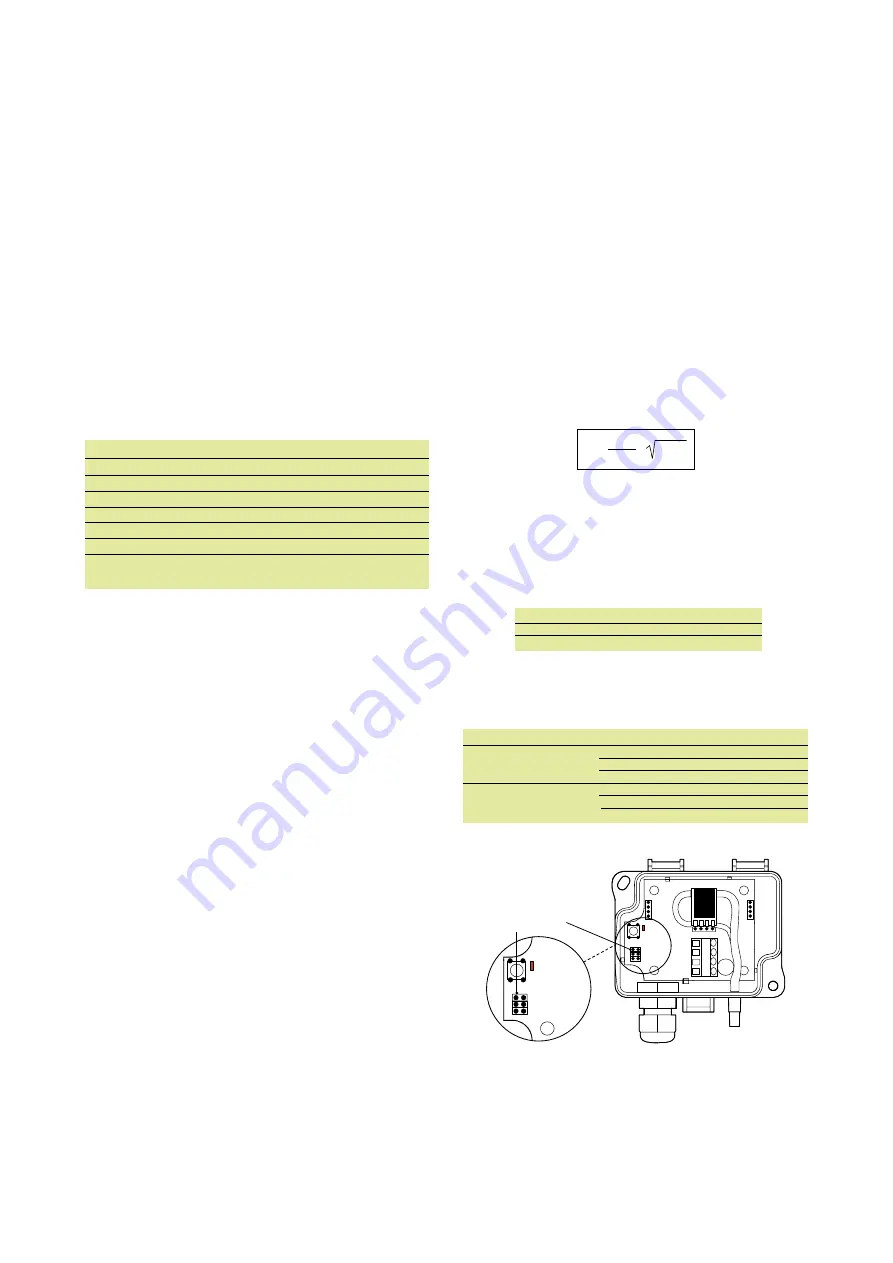

4-20mA

LED

Jumper 1

Jumper 2

Jumper 3 24VDC

GND

0-10V

LED

Jumper 1

Jumper

2

Jumper

3

push-button

Pressure control regulates air pressure in index duct (duct

with a maximum pressure drop, and where the static pres-

sure is lowest). The pressure sensor (GP3) is placed at the

beginning of this duct The exhaust sensor (GP4) is placed

in the exhaust duct at a suitable location with representa-

tive pressure. For settings see the Parameter list.

Constant Flow Control (CAV)

Control principle in which the unit maintains a constant

duct flow. Pressure sensors are supplied as loose accesso-

ries. Using a measurement pressure

D

pm in Pa and a con-

stant k, the airflow q in l/s is calculated with the follo wing

formula:

q = 1000

k

D

p

m

x

The measuring pressure,

D

pm, is the difference between

the pressure in the empty section at the fan inlet and the

pressure inside the inlet cone.

The pressure sensor is connected via two externally

placed measuring nipples.

Value of the constant (k) is shown in the table below.

For settings see the parameter list.

Zero point-calibration

Connection of pressure sensors

The pressure sensor shall be set to the working range of

0 –500 Pa.

Location

Terminal Connection No.

Pressure sensor

Y

52 0

–

10 V

Supply air duct

GP3

G0

51

GND

G

50

24 V DC

Y

55 0

–

10 V

Extract air duct GP4

G0

54

GND

G

53

24 V DC

The sensors must be zeroed during commissioning. They

should then be zeroed annually. The sensors should have

been energized for approximately one hour before cali-

bration is carried out. After that, remove the hoses from

the sensors. To start calibration press the push-button

next to the pressure range jumpers. The red LED lights

up and goes out after about a second. Reassemble the air

hoses. Done!